- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

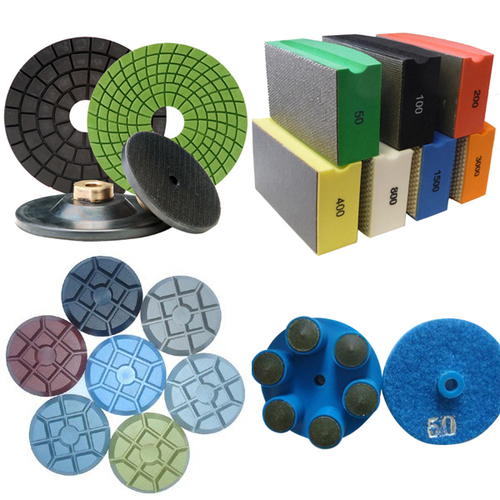

Diamond Concrete Polishing Disc pad

Product Details:

- Product Type Concrete Polishing Disc Pad

- Diamond Cut Segmented

- Diamond Shape Round

- Purity Industrial Grade

- Enhancements No Enhancement

- Size 4 Inch (Approx.)

- Click to View more

X

Diamond Concrete Polishing Disc pad Product Specifications

- 4 Inch (Approx.)

- No Enhancement

- Round

- Concrete Polishing Disc Pad

- Segmented

- Industrial Grade

Product Description

We are a prominent enterprise, successfully committed in putting forward an excellent quality Diamond Concrete Polishing Disc pad. The offered pad is manufactured with the use of premium quality raw materials under the supervision of our adroit professionals. This pad is especially utilized in construction and furnishing applications for polishing concrete surface efficiently. Additionally, we provide this Diamond Concrete Polishing Disc pad in different sizes and dimensions at reasonable prices to our clients.

Features:

Features:

- Uniform thickness

- Supreme finish

- Reusable

- Crack proof surface

Superior Polishing Performance

Utilizing diamond-impregnated resin, these pads effectively polish both wet and dry concrete floors, yielding a glossy, professional finish. The high durability extends the pads lifespan, making it ideal for commercial and industrial applications requiring reliable results.

Versatile and User-Friendly Design

With a 4-inch size and Velcro backing, these pads can be easily attached to most handheld grinder and polisher machines. The color-coded grits, from 50 to 3000, simplify the selection process for different polishing stages and surface requirements.

FAQs of Diamond Concrete Polishing Disc pad:

Q: How do I use the Diamond Concrete Polishing Disc pad for optimal results?

A: To achieve optimal polishing, attach the Velcro-backed pad to your handheld grinder or polisher. Begin with a lower grit for rough surfaces and progressively move to higher grits for a smooth, glossy finish. Suitable for both wet and dry applications, ensure you verify the machines compatibility with 4-inch pads.Q: What surfaces can these diamond polishing pads be used on?

A: These pads are designed for concrete floor polishing but can also be used on other suitable masonry surfaces. The industrial-grade diamond resin composition ensures effective results on a variety of hard surfaces.Q: When should I change to a higher grit pad during the polishing process?

A: Switch to a higher grit pad once the surface appears uniformly smooth and free from previous scratches. Typically, the process starts with a coarse 50 or 100 grit and advances in sequence up to 3000 for a glossy finish.Q: Where are these diamond polishing pads manufactured and distributed?

A: These pads are manufactured, supplied, and exported from China, offered by experienced distributors and manufacturers catering to global markets.Q: What benefits do these pads provide compared to conventional polishing pads?

A: The diamond-impregnated resin delivers superior abrasion and longevity, providing a high-gloss, smooth finish while minimizing wear. The segmented, round-cut design further enhances performance and dust management.Q: How does the Velcro backing enhance usability during the polishing process?

A: Velcro backing allows for quick and secure pad changes, improving workflow efficiency and reducing downtime during multi-step polishing operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Polisher Pads' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |