- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

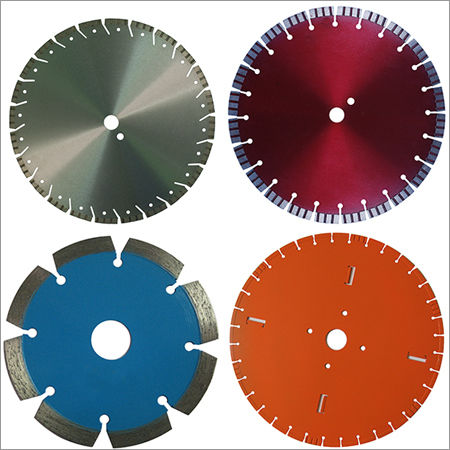

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

Sintered Mounted Stones

Product Details:

- Product Type Mounted Stones

- General Use Grinding, Deburring, Finishing

- Material Sintered Aluminum Oxide

- Type Cylindrical, Ball, Cone, Bullet (Variety of shapes)

- Capacity Depends on application

- Weight (kg) Approx. 0.02 0.1 kg each

- Cutting Speed Max 20,000 RPM

- Click to View more

X

Sintered Mounted Stones Price And Quantity

Sintered Mounted Stones Product Specifications

- No slot

- Pink, Blue or Brown (depends on grit & formulation)

- Approx. 0.02 0.1 kg each

- Solid Sintered

- Cylindrical, Ball, Cone, Bullet (Variety of shapes)

- Mounted Stone

- Head Dia: 3mm 25mm; Shank: 3mm or 6mm

- Rotary / Electric / Pneumatic Tools

- Abrasive Grit

- Max 20,000 RPM

- Sintered Aluminum Oxide

- Depends on application

- High Durability, Precision Shaping, Consistent Performance

- Mounted Stones

- Grinding, Deburring, Finishing

Product Description

Backed by our team of experienced professionals, we have attained the position of being one of the trusted manufacturers, suppliers and exporters of a wide range of Sintered Mounted Stones. Offered product is manufactured using high grade raw material with the aid of sophisticated machinery. Our range is highly appreciated for its dimensional accuracy, perfect finish, smooth functionality and durability. Clients can avail these Sintered Mounted Stones in various standard and customized specifications from us.

Special Attractions

- These have rugged design and are easy to use

- Components used during manufacturing are of international quality standards

- Latest machinery and tools are utilized by our experienced professionals

- We are exporting these to different markets of the world

- We provide timely delivery of the orders

- Appreciated for their unmatched performance

- Have long operational life and have negligible maintenance

- These are available at pocket friendly prices

|

Product Detail: |

|

|

Product Name: |

Sintered Mounted Stones |

|

Product Code: |

SPT801 |

|

Brand Name: |

SHINE PEAK DIAMOND |

|

Model Number: |

SHINE PEAK - SPT801 |

|

Certification: |

ISO9002 |

|

Condition : |

New |

|

Business type |

Manufacturer, Exporter and Supplier |

|

Payment Terms : |

T/T or L/C any payment can be possible |

|

Price: |

USD/EURO/RMB |

|

Warranty: |

6 month |

|

Material / Metal Processed |

Diamond & Alloy Steel |

|

Monthly Production Capacity: |

10 Pieces |

|

|

|

|

Machine Technical Specification: |

|

|

Dimension / Standard Size Range: |

Can be customized |

|

Raw Material: |

Stone & Stainless Steel |

|

Use / Application: |

Industrial used |

|

Finishing: |

Painted / Ti-coated |

|

Color: |

any color and Up to Client requirement |

|

Quality: |

Professional |

|

Extra Services: |

OEM Service and Custom |

|

|

|

|

Packaging & Delivery Detail: |

|

|

Packaging Detail: |

As per international standard |

|

Delivery Detail: |

20 to 30 in working days |

|

Shipment By: |

Sea, Air, Road Transportation |

Versatile Shape and Grit Size Selection

Choose from ball, cylinder, taper, and bullet shapes, each available in grit sizes from 46 to 240. This flexibility allows users to tailor their abrasive stone selection to specific material removal and surface finishing needs, ensuring optimal results for every application.

Designed for High-Speed Precision

Crafted with medium to hard grades and a recommended RPM range of 10,000 20,000, these mounted stones excel in both fine and aggressive grinding. The high-grade steel shank and solid sintered segment ensure stability and long-lasting use, even during high-speed operations.

OEM Customization for Unique Requirements

Our sintered mounted stones can be customized according to your exact specifications on shape, size, grit, and color. With OEM solutions available, distributors and manufacturers can achieve precise compatibility with their operational needs and brand standards.

FAQs of Sintered Mounted Stones:

Q: How are sintered mounted stones typically used in industrial applications?

A: Sintered mounted stones are primarily utilized for grinding, deburring, and surface finishing tasks. Their abrasive properties and variety of shapes make them ideal for precision shaping and smoothing of metals, alloys, and other hard materials.Q: What grit sizes are available for these vitrified bond mounted stones?

A: Grit sizes from 46 to 240 can be provided as per requirement, allowing users to select coarse to fine abrasives depending on their specific process needs.Q: When should I select medium versus hard grade hardness for my application?

A: Medium grade stones are suited for general finishing and deburring, while hard grade stones are ideal for heavy-duty grinding or shaping tasks requiring greater abrasion resistance and less wear.Q: Where can these mounted stones be used, and what tools are compatible?

A: They are compatible with rotary, electric, and pneumatic tools and are used in manufacturing workshops, metal fabrication units, and maintenance operations requiring high-precision abrasive work.Q: What is the benefit of OEM customization for these mounted stones?

A: OEM customization allows you to specify the exact shape, size, grit, and even color, ensuring optimal performance and integration with your unique production processes or branding requirements.Q: How does the heat and chemical resistance feature enhance usage?

A: These stones are engineered to withstand high temperatures and aggressive chemicals, enabling reliable, consistent performance during prolonged operations or when processing tough materials.Q: What packing options are available for distributors and exporters?

A: Products can be supplied in blister packs for retail or bulk boxes for high-volume distribution, meeting the needs of suppliers and manufacturers for secure and convenient handling.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cutting Tools ' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |