- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

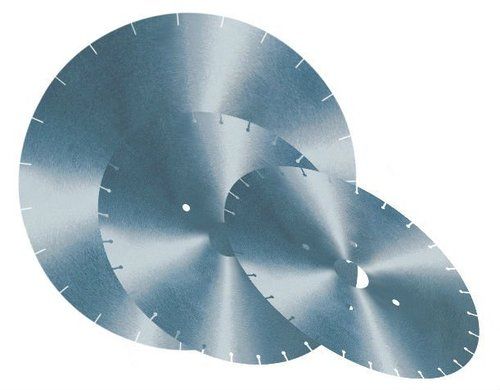

Sintering Brazed Blade

Product Details:

- Product Type Sintering Brazed Blade

- General Use Industrial metal and stone cutting

- Material Feature High hardness, wear resistance

- Type Cutting Blade

- Capacity Standard, as per application

- Weight (kg) 0.4 kg (approx)

- Cutting Type Dry/Wet cutting

- Click to View more

X

Sintering Brazed Blade Product Specifications

- 1.6 mm

- Sharp cutting edge, stable performance

- Sintering Brazed Blade

- Standard U/gullets

- Diamond alloy, metal bond

- 10 mm

- 110 mm

- 1.6 mm

- 22.23 mm

- Silver/Metallic

- Standard, as per application

- 8 segments

- Cutting Blade

- Segmented

- Industrial metal and stone cutting

- High hardness, wear resistance

- Anti-corrosion

- Dry/Wet cutting

- 0.4 kg (approx)

- Sintered + Brazed

Product Description

We are an eminent manufacturer, exporter and supplier of high quality Sintering Brazed Blade. The offered blade is used for polishing and cutting of granite, basalt, limestone, dolomite, sandstone, marble and other stone. It is manufactured in our technically sound manufacturing unit using premium quality raw material and advanced machinery by our professionals. We also test our provided blade on diverse parameters to ensure its high strength and perfection. We are offering this Sintering Brazed Blade in varied sizes according to the needs of our clients.

Features:

- Compact design

- Corrosion proof

- Easy installation

- Perfect finish

Other Details:

| Name | Sintering Brazed Blade | HS code | 8202390000 |

| Process | Silvered Welded and Coppered Welded | Material | Diamond & Steel |

| Abrasive | Diamond | Packing | 1pcs / Blister |

| Size | 250mm, 300mm, 350mm, 400mm, 500mm, 800mm etc | OEM/ODM | Available |

| Type code | Any colour and segments sizes are available for DIY design. | ||

Engineered for a Variety of Materials

Tackle tough jobs on granite, marble, concrete, tile, and general masonry with a blade that excels in both dry and wet cutting. Its segmented rim and diamond alloy composition ensure precise, clean results while reducing chipping.

High Performance and Durability

The sintered and brazed manufacturing process gives the blade exceptional hardness and wear resistance, supporting extended operational life. Polished surface finish and anti-corrosion coating safeguard against environmental stress for consistent performance.

Flexible & Efficient Use

Easily installable on most standard angle grinders, this blade manages rotational speeds up to 13,800 RPM and maintains a stable, sharp cutting edge. Its low noise level and smooth operation permit comfortable use in various industrial settings.

FAQs of Sintering Brazed Blade:

Q: How do I install the Sintering Brazed Blade on my angle grinder?

A: Ensure your grinder is compatible with the blades 22.23 mm arbor size. Follow the manufacturers instructions for the correct installation, ensuring all safety precautions are taken before use.Q: What materials can this blade effectively cut?

A: The blade is designed to cut granite, marble, concrete, tile, and general masonry. Its diamond alloy segments and high hardness ensure optimal performance across these materials.Q: When should I choose this blade over traditional cutting tools?

A: Opt for this blade when you need a highly durable, precision cutting solution with low noise and minimal chipping, especially for industrial metal and stone cutting applications.Q: Where should I store the blade when not in use?

A: Store the blade in a dry, well-ventilated location to prevent corrosion and preserve its polished surface and cutting effectiveness.Q: What is unique about the manufacturing process of this blade?

A: This blade is manufactured using sintering and brazing at high temperatures, resulting in improved segment bonding, higher hardness, and enhanced heat resistance.Q: How does the blades segmented design benefit cutting tasks?

A: The segmented rim allows for efficient debris removal and reduces heat buildup, ensuring a smooth, chip-free finish and stable performance during operation.Q: What advantages does the blade offer for industrial users?

A: Industrial users benefit from the blades extended life, sharp cutting edge, robust heat resistance, and consistent performance, making it ideal for demanding cutting tasks in construction and fabrication.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Saw Blades' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |