- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

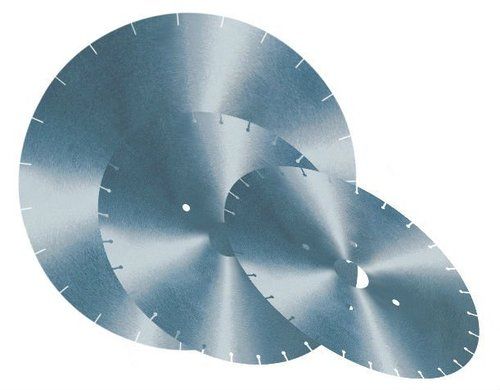

Tuck Point Diamond Blades

Product Details:

- Product Type Tuck Point Diamond Blades

- General Use Grooving or routing out mortar, cement seams and joints in masonry, concrete, and stone works

- Type Segmented Blade

- Cutting Type Dry and Wet Cutting

- Arbor 22.23 mm (other arbor sizes available upon request)

- Diameter of Disc 110 mm, 125 mm, 150 mm, 180 mm

- Teeth Type Segmented Tuck Point

- Click to View more

X

Tuck Point Diamond Blades Product Specifications

- 22.23 mm (other arbor sizes available upon request)

- 110 mm, 125 mm, 150 mm, 180 mm

- Segmented Tuck Point

- Grooving or routing out mortar, cement seams and joints in masonry, concrete, and stone works

- Silver/Grey (segment), Blue/Red (body options)

- Cold pressed and laser welded

- Tuck Point Diamond Blades

- Segmented Blade

- Dry and Wet Cutting

- 6 mm, 8 mm, 10 mm

- 10 mm

Product Description

Ours is a remarkable firm, indulged in manufacturing, supplying and exporting a qualitative array of Tuck Point Diamond Blades. Sophisticated techniques and advanced machinery is used in manufacturing unit for designing of these diamond blades. Owing to their precise dimensions, perfect finish, excellent operational speed and high corrosion resistance, offered blades are highly applauded in the market. Clients can avail these Tuck Point Diamond Blades in various specifications and that too within stipulated time frame.

Special Attractions:

- Components and raw materials obtained from vendors are of supreme quality

- These are available in various sizes and designs as per the preference of the clients

- Superior quality packaging materials are used to ensure safe delivery

- Appreciated for their features like long working life and unmatched performance

- Complete know-how about the usage is given to the clients

- Demanded by various industries around the world for their negligible maintenance and rugged design

- Latest machine and modern gadgets are used in their fabrication

- No inferior component or materials are used

| Product Detail: | |

| Product Name: | Tuck Point Diamond Blades |

| Product Code: | SPT704 |

| Brand Name: | SHINE PEAK DIAMOND |

| Model Number: | SHINE PEAK SPT704 |

| Certification: | ISO9002 |

| Condition : | New |

| Business type | Manufacturer, Exporter and Supplier |

| Payment Terms : | T/T or L/C any payment can be possible |

| Price: | USD/EURO/RMB |

| Warranty: | 6 month |

| Material / Metal Processed | Diamond & Alloy Steel |

| Monthly Production Capacity: | 10 Pieces |

| Machine Technical Specification: | |

| Dimension / Standard Size Range: | 105mm to 270mm |

| Raw Material: | Diamond & Alloy Steel |

| Use / Application: | Industrial area |

| Finishing: | Painted / Ti-coated |

| Color: | any color and Up to Client requirement |

| Quality: | Professional |

| Extra Services: | OEM Service and Custom |

| Packaging & Delivery Detail: | |

| Packaging Detail: | As per international standard |

| Delivery Detail: | 20 to 30 in working days |

| Shipment By: | Sea, Air, Road Transportation |

Powerful Cutting for Masonry and Stone

These Tuck Point Diamond Blades are designed for precision work on mortar, concrete, masonry, brick, and stone. The segmented teeth and laser-welding technology ensure consistent performance and extended segment life, even under demanding site conditions. Their engineered vibration damping core effectively minimizes noise for a better operating experience.

Adaptable to Various Tools and Applications

Available in diameters of 110 mm, 125 mm, 150 mm, and 180 mm, with arbor sizes of 22.23 mm or custom options, these blades suit a wide range of machines. Whether your project requires dry or wet cutting, their compatibility and reliability make them suitable for both jobsite efficiency and high-quality results.

Long Life and Superior Packaging Options

Built to deliver excellent longevity, these blades maintain their cutting edge through repeated use. Advanced cold-pressed and laser-welded manufacturing ensures segment integrity. Blades are supplied in individual boxes or bulk packaging, accommodating distributor, exporter, manufacturer, and supplier needs.

FAQs of Tuck Point Diamond Blades:

Q: How should I use Tuck Point Diamond Blades for optimal performance and lifespan?

A: To maximize blade life, always run the blades within their speed limits and use the appropriate segment thickness for your application. Employ wet or dry cutting methods as suited, and routinely check for wear and debris build-up. Proper usage avoids overheating and extends the longevity of laser-welded segments.Q: What materials are suitable for cutting with these tuck point blades?

A: These blades are designed to efficiently groove and route out mortar, concrete, masonry, brick, and stone. Their robust construction ensures clean cuts and reliable performance on even the hardest jobsite materials.Q: When is it recommended to use wet cutting versus dry cutting with these blades?

A: Wet cutting is advised for extended operation or when working on dense materials, as water cools the blade and helps reduce dust. Dry cutting can be used for quick jobs or where water isnt feasible, but operators should allow the blade to cool intermittently during extended dry use.Q: Where can I order these blades, and are custom arbor sizes available?

A: Tuck Point Diamond Blades are available through distributors, exporters, manufacturers, and suppliers based in China. Custom arbor sizes can be requested to suit specific machines or project requirements, ensuring flexibility for diverse applications.Q: What is the process behind the segment attachment, and how does it benefit durability?

A: The blade segments are attached using advanced laser welding, which ensures a strong bond and high resistance to segment loss during demanding cutting tasks. This process enhances blade durability and maintains cutting efficiency over a longer working life.Q: How does the engineered core help in noise reduction during cutting operations?

A: The blade core is specifically designed to dampen vibration, which significantly lowers noise levels while in use. This results in a quieter work environment and more comfortable operation for users, especially during prolonged periods of cutting.Q: What packaging options are available for bulk orders or individual purchases?

A: Blades are supplied in individual boxes for ease of identification and storage, or in bulk packaging for large-volume orders. This flexible packaging system accommodates the needs of distributors, exporters, and suppliers, providing convenience and efficiency in inventory management.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Saw Blades' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |