- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

CNC Diamond Router Bit

Product Details:

- Product Type Router Bit

- General Use CNC Stone Cutting and Profiling

- Material Industrial Grade Diamond with Alloy Steel Body

- Type Diamond Tipped Router Bit

- Capacity Heavy Duty Continuous Operation

- Weight (kg) 0.85 kg

- Cutting Speed High-speed, up to 15000 RPM

- Click to View more

X

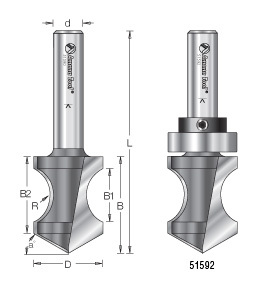

CNC Diamond Router Bit Product Specifications

- Industrial Grade Diamond with Alloy Steel Body

- Diamond Tipped Router Bit

- Diameter 20 mm x Length 50 mm

- Long Working Life, Smooth Finish, Fast Cutting

- Standard Flute Slots

- High-speed, up to 15000 RPM

- Silver Grey with Diamond Grit

- Profile Cutter

- Heavy Duty Continuous Operation

- 8 Segments

- 0.85 kg

- Router Bit

- CNC Stone Cutting and Profiling

- N/A (Passively Driven)

- 0.2 mm - 20 mm

- Shank Mounted for CNC Machines

- Laser Welded Diamond Segment

- Precision Diamond Teeth

Product Description

For serving our national as well as international clients, our firm is engaged in offering premium quality CNC Diamond Router Bit. Being a quality-oriented organization, we assure our clients that provided bit is the best in quality and is manufactured by our deft team of experts utilizing fine quality metal alloy and contemporary machines. It is widely used for giving a high quality cut finish on a range of materials including woods, foams, plastics and aluminum. Moreover, our offered CNC Diamond Router Bit can be availed in a wide range of sizes as per the requirements of our esteemed clients.

Features:

- Corrosion proof

- Sharp edges

- Sharpening efficiency

- Application specific design

Applications:

- Solid Carbide tooling having a sole upward spiral flute.

- Mainly effective for machining acrylics to generate a smooth and steady finish.

- The upward spiral flute geometry ensures excellent chip clearance.

Other Details:

| Name | Diamond CNC Router Bit | HS code | 8202390000 |

| Process | Brazed | Material | Carbide Steel |

| Abrasive | Diamond | Packing | Paper Box |

| Size | 20mm-100mm,etc | OEM/ODM | Available |

| Type code | Any colour and sizes are available for DIY design. | ||

Package:Right size in Paper Box,according to your request with high quality carton box

Engineered for Precision and Durability

Featuring eight laser-welded segments and precision diamond teeth, this router bit excels in stone profiling tasks. Its robust alloy-steel body is designed to handle high-speed cutting and continuous operation, ensuring superior reliability for professional stonework applications. Use with CNC routers for seamless, automatic bit changes and ultra-fine finishes.

Universal Compatibility and Efficient Operation

Compatible with most CNC router machines, the 12 mm shank fits securely and works with automatic tool changers. Whether profiling granite, marble, or engineered stones, benefit from fast cutting speeds and smooth, consistent results. Water cooling extends the bits life and maintains performance in both wet and dry environments.

Safe, Reliable Packaging and Use

Each diamond router bit comes in a shockproof protective case for secure handling and shipping. Its low noise performance improves workshop environments, while the industrial-grade diamond ensures longevity and reduced maintenance costs, making it a trusted choice for distributors, exporters, and manufacturers in the stone cutting industry.

FAQs of CNC Diamond Router Bit:

Q: How is the CNC Diamond Router Bit installed and used on CNC machines?

A: The router bit features a 12 mm shank designed for universal compatibility with CNC router machines. Simply mount it into the spindle or tool holder, ensuring the tool changer mechanism is set for automatic operation. Always follow manufacturer guidelines for installation and initiate water cooling during prolonged cutting sessions.Q: What types of stone materials can this diamond router bit profile and shape?

A: This bit is suitable for profiling and edge shaping granite, marble, quartz, and artificial stone. Its heavy-duty diamond segments offer consistent performance even with hard, abrasive stones and engineered composites used in countertops and decorative stonework.Q: When should water cooling be used with this router bit?

A: Water cooling is recommended for extended use or when working with dense stone materials. It helps dissipate heat, preserves diamond integrity, and prolongs the bits operational life, especially during continuous heavy-duty cutting at high feed rates.Q: Where is this router bit manufactured and supplied from?

A: The CNC Diamond Router Bit is produced in China and distributed globally by manufacturers, suppliers, exporters, and distributors specializing in industrial stone-cutting tools.Q: What is the process for achieving an ultra-fine finish on stone edges with this bit?

A: To attain an ultra-fine finish, operate the bit within recommended speed (up to 15,000 RPM) and feed rate (maximum 2.5 m/min), using water cooling for optimal performance. The precision diamond teeth and laser welded segments work together to deliver smooth, accurately shaped edges.Q: What are the benefits of using this diamond router bit compared to traditional cutters?

A: Benefits include longer working life (up to 1200 linear meters), faster cutting speeds, ultra-fine finish quality, low noise output, and compatibility with automatic CNC tool changers. The industrial-grade diamond segments reduce wear and improve efficiency over traditional carbide or steel cutters.Q: Is the router bit ready for immediate use upon delivery?

A: Yes, each bit is securely packed in a shockproof protective case, pre-mounted with laser welded diamond segments and standard flute slots, ready for installation on CNC machines upon unpacking.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |