- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

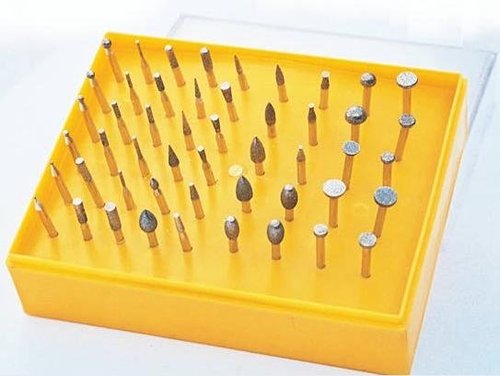

Industrial Diamond Mounted Points

Product Details:

- Product Type Industrial Diamond Mounted Points

- General Use Precision Grinding, Deburring, Surface Finishing, Polishing

- Material Industrial Grade Diamond, Metal Bond

- Type Mounted Point

- Capacity Suitable for Manual and Automated Machines

- Weight (kg) 0.02 kg (per piece, approx.)

- Cutting Speed Up to 35,000 RPM

- Click to View more

X

Industrial Diamond Mounted Points Product Specifications

- Mounted Point

- Direct Drive, Handpiece Compatible

- Industrial Diamond Mounted Points

- Suitable for Manual and Automated Machines

- Diamond Abrasive

- N/A (Non-electric tool)

- Cylindrical, Conical, Ball, Tapered, Custom Shapes

- Industrial Grade Diamond, Metal Bond

- Single Segment

- Precision Grinding, Deburring, Surface Finishing, Polishing

- High Wear Resistance, Fast Material Removal, Long Service Life, Uniform Finishing

- Available Diameters: 3mm, 5mm, 6mm, 10mm, Custom Sizes

- No Slot

- Up to 35,000 RPM

- 0.02 kg (per piece, approx.)

- Varies by Size (usually 1mm to 12mm)

- Rotary Grinding Tool

- Silver/Gray (Diamond), Shank in Metallic Finish

Product Description

Owing to the changing trend, we are engaged in offering large array of Diamond Mounted Points. These mounted points are widely used for smoothing, shaping and removing hardened steel, fired ceramics, plastic, stainless steel and hardwoods. Offered mounted points are manufactured under the supervision of our experts by making use of quality tested raw material with the aid of latest manufacturing techniques. We offer our provided mounted points to our clients in the stipulated time frame to meet their demand. These Diamond Mounted Points are provided at reasonable prices after testing them for product perfection.

Features:

- Fine grip

- Durability

- Easy to fit

- High strength

| Name | Brazed or electroplated diamond graver/Mounted points | HS code | 8202390000 |

| Process | Brazed or electroplated | Material | Carbide Diamond |

| Abrasive | Diamond Graver Mounted points | Packing | 12pcs / Blister |

| Size | 2.35mm, 3.00mm, 6.00mm, or upon request | OEM/ODM | Available |

Versatile Industrial Application

Our diamond mounted points are engineered to tackle hard-to-machine materials such as carbide, ceramics, stone, glass, and hardened steel. Ideal for both manual and automated processes, they support high-speed rotary grinding and ensure uniform finishes, making them suitable for varied industries including manufacturing, construction, and precision tooling.

Customizable Shapes and Sizes

With standard shank diameters of 3mm and 6mm, we also offer custom dimensions and segment typescylindrical, tapered, ball, conicalalongside custom grit options. This flexibility caters to specialized tasks, ensuring the right tool for every unique operation, whether fine polishing or aggressive material removal.

Superior Durability and Performance

Composed of industrial grade diamond grits set in a metal bond, our mounted points offer high wear resistance, fast material removal rates, and extended service lifespans. They operate reliably at temperatures up to 200C and speeds reaching 35,000 RPM, delivering consistent, high-quality results even under demanding conditions.

FAQs of Industrial Diamond Mounted Points:

Q: How do I select the right diamond mounted point for my specific application?

A: Choose your diamond mounted point by considering the material to be worked on, the desired surface finish, the grit size (from 60 for coarse finishing to 400 for fine finishing), and the shape required for your process. Custom sizes and grits are available to match special requirements.Q: What are the operating and compatibility features of these mounted points?

A: These mounted points operate at cutting speeds up to 35,000 RPM and temperatures up to 200C. They fit standard rotary, pneumatic, and electric handpieces and can be used with both manual and automated machines, ensuring flexible use across different tool platforms.Q: When should I use metal-bonded diamond mounted points instead of resin or vitrified bonds?

A: Opt for metal-bonded diamond points when you require high hardness, extended tool life, uniform finishes, and fast material removal, particularly for grinding or finishing challenging hard materials such as carbide, glass, and ceramics.Q: Where are these mounted points manufactured and supplied from?

A: These diamond mounted points are manufactured under ISO 9001:2015 standards in China and are available for distribution, export, wholesale, and supply worldwide, ensuring reliable quality and consistent availability.Q: What is the minimum order quantity and packaging options available?

A: The minimum order quantity is 100 pieces. We offer multiple packaging types, including blister packs, plastic boxes, and bulk packaging to suit distributor, manufacturer, and end-user needs.Q: How can I ensure optimal tool life and safety during usage?

A: Use the mounted points within their recommended speed (up to 35,000 RPM) and temperature (max 200C) limits. Ensure proper mounting in compatible handpieces and avoid excessive pressure to minimize tool wear and maximize safety.Q: What are the key benefits of using industrial diamond mounted points?

A: Key benefits include high wear resistance, fast material removal, precise and uniform surface finishing, long service life, and versatility for various shapes, grits, and tool compatibility, enabling reliable performance even for demanding grinding and polishing tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |