- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

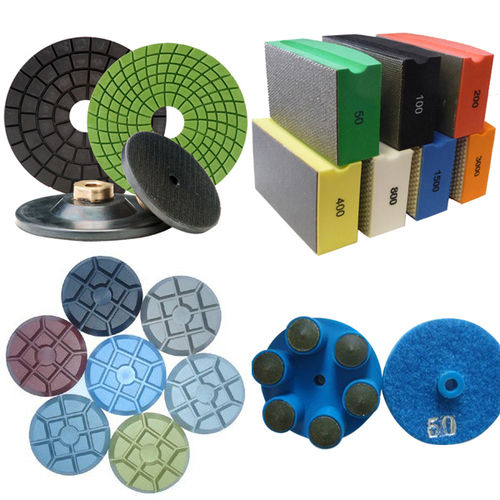

Diamond Polishing Pad

Product Details:

- Product Type Diamond Polishing Pad

- Diamond Cut Segmented

- Diamond Shape Round

- Purity Industrial Grade

- Enhancements Resin Bond, Flexible Design

- Size 4 inch (Can vary: 3, 4, 5, 7 inch available)

- Click to View more

X

Diamond Polishing Pad Product Specifications

- Round

- Industrial Grade

- Resin Bond, Flexible Design

- 4 inch (Can vary: 3, 4, 5, 7 inch available)

- Segmented

- Diamond Polishing Pad

Product Description

We are well-established name in industry, engaged in manufacturing, exporting and supplying a wide gamut of Diamond Polishing Pad. Only high quality raw material and advanced technology is used while manufacturing these pads, for increased compliance with international market standards of quality. It is commonly used to polish, restore and maintain the floor of concrete, terrazzo, marble, granite, etc. Apart from this, our offered range of Diamond Polishing Pad is offered in different specifications and can be customized, as per precise needs of our clients and at highly competitive prices.

Features:

- Simple to fit

- Smooth finish

- Dimensional accuracy

- Precisely designed

Diamond Hand Polishing Pads

- Technical:Wet or Dry

- Grit size :Different cutting purpose with different diamond grits#

- Sizes:4",5",6",8" etc

- The colour and sizes could be made as customer's requirements

Application:

- They are precisely designed for floor polishing machine to polish as well as restore or maintain the floor of concrete, marble, terrazzo and granite. They are supported with Velcro that can be easily mounted on a stiff backer pad to suit any floor machine.

- Used for polishing granite, marble and other special-sharpened stone of the corner.

- We have gained a good reputation in the market for this kind of product.

- Easy use and ensure effective grinding as well as polishing concrete floor

- After polishing, the stone surfaces show a mirror effect.

Advanced Resin Bond with Diamond Precision

Each pad features a superior resin bond matrix embedded with high-purity, industrial-grade diamond particles shaped in a segmented, round configuration. This design enhances cutting efficiency, durability, and polishing finesse for both wet and dry processes, providing superior results on a variety of hard surfaces.

Flexible, Color-Coded Polishing Solution

With multiple grit options and a flexible design, these pads address a broad spectrum of polishing needs, from coarse grinding (grit 50) to ultra-fine finishing (grit 3000). The color-coded pads ensure quick identification of grit level, while sizes from 3 to 7 inches cater to different job requirements and machine compatibilities.

FAQs of Diamond Polishing Pad:

Q: How should the Diamond Polishing Pads be used for both wet and dry polishing?

A: These pads are compatible with angle grinders and polishing machines. For wet polishing, apply water to the surface to minimize dust and heat. For dry use, work in a well-ventilated area and follow safety guidelines. Progress through grits sequentially for optimal shine and smoothness.Q: What surfaces can the Diamond Polishing Pads polish effectively?

A: They are suitable for various hard surfaces including marble, granite, concrete, natural stone, and tiles, making them ideal for construction, restoration, or stone countertop finishing projects.Q: When should I change to a higher or lower grit pad during the polishing process?

A: Start with a lower grit (50 or 100) to remove scratches or surface impurities. Move to progressively higher grits (up to 3000) once the previous scratches have been eliminated, refining the finish at each step for a glossy result.Q: Where can these pads be used, considering their water resistance and flexibility?

A: Their water-resistant, flexible design allows for use in kitchens, bathrooms, outdoor areas, or construction sitesessentially anywhere flat or contoured stone surfaces need polishing.Q: What are the main benefits of using these pads with Velcro backing?

A: Velcro backing enables quick pad changes, improving efficiency during multi-stage polishing while ensuring a secure connection to your polishing machine or angle grinder.Q: How does the honeycomb or spiral pattern impact the polishing process?

A: The honeycomb or spiral pattern ensures continuous contact with the surface, promotes efficient slurry removal, and enhances cooling, resulting in a smooth, consistent finish without surface overheating.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Polisher Pads' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |