- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

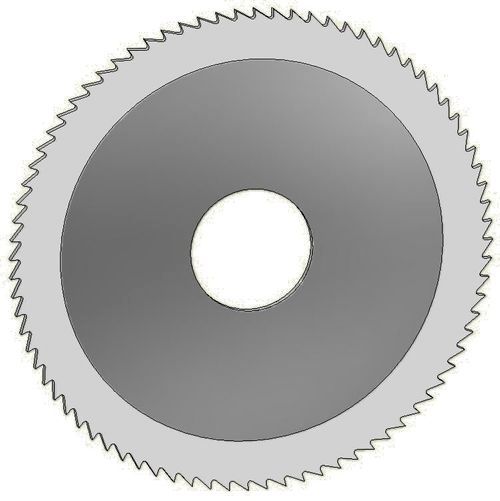

Thin Circular Saw Blade

Product Details:

- Product Type Thin Circular Saw Blade

- General Use Precision Wood, Metal and Plastic Cutting

- Material Feature High Speed Steel (HSS), Carbide Tipped

- Type Saw Blade

- Capacity Industrial and Workshop Use

- Weight (kg) Approx. 0.2 - 0.8

- Cutting Type Fine, Clean Cut

- Click to View more

X

Thin Circular Saw Blade Product Specifications

- 16 mm, 20 mm, 22.23 mm (as per requirement)

- 110 mm to 250 mm

- Thin Circular Saw Blade

- Metallic Silver, Gold-Toned, Blue (coating may vary)

- Anti-Corrosion, Non-Stick

- Expansion Slots for Anti-Vibration

- Varies as per diameter (e.g., 24, 36, 60T)

- Laser-Cut, Brazed Teeth

- 3 mm to 10 mm

- High Grade Alloy/Steel with Carbide Tipped Edges

- 0.8 mm to 2.2 mm

- Fine, Clean Cut

- Alternate Top Bevel (ATB), Triple Chip

- Industrial and Workshop Use

- Precision Wood, Metal and Plastic Cutting

- Thin Kerf (0.8 mm - 2.2 mm)

- Saw Blade

- High Speed Steel (HSS), Carbide Tipped

- Rust Resistant, Smooth Finish, Long Life

- Approx. 0.2 - 0.8

Product Description

Relying on our up-to-date infrastructure, we are able to manufacture, export and supply Thin Circular Saw Blade. This saw blade is manufactured by utilizing premium quality raw material with the aid of pioneering technology. The offered saw blade is used for granite, basalt, limestone, dolomite, sandstone, marble and other stone cutting and polishing. In order to meet the varied needs of the client, our provided blade is offered in various sizes and specifications as per the requirements of the clients. Our clients can purchase this Thin Circular Saw Blade from us at market leading prices.

Features:

- Accurate dimension

- Easy to fit

- Corrosion resistance

- Flawless finish

Other Details:

| Name | Diamond Cutting Blades | HS code | 8202390000 |

| Process | Silvered Welded and Coppered Welded | Material | Diamond & Steel |

| Abrasive | Diamond | Packing | 1pcs / Blister |

| Size | 4",5",6",8" etc | OEM/ODM | Available |

| Type code | Any colour and segments sizes are available for DIY design. | ||

Precision Engineering for Versatile Cutting

Crafted for both industrial and continuous workshop use, this thin circular saw blade excels at precision tasks. Its alternate top bevel (ATB) or triple chip teeth, combined with thin kerf and high-grade materials, optimize cutting speed and finish while minimizing waste. The blades advanced laser-cut expansion slots ensure quieter operation with reduced vibration.

Durable High-Speed Steel with Premium Coating

Combining high-speed steel and carbide-tipped edges, the blade offers extended lifespan, rust resistance, and heat resilience up to 250C. Advanced anti-corrosion and non-stick coatings further support smooth cutting across wood, metal, and plastics, making it adaptable for demanding industrial environments.

FAQs of Thin Circular Saw Blade:

Q: How does the thin circular saw blade enhance precision and cutting efficiency?

A: The blades thin kerf design, along with fine, polished or coated finishing and segment options such as alternate top bevel or triple chip, enhance the accuracy and cleanliness of each cut. Laser-cut expansion slots further minimize vibration and noise, improving performance in heavy-duty operations.Q: What applications are suitable for this circular saw blade?

A: It is ideal for use in circular saws, table saws, and panel saws, making it versatile for industrial and workshop settings. The blade excels in cutting wood, metal, and plastic materials with recommended thicknesses between 1 mm and 25 mm.Q: When should I choose a blade with a particular segment number or diameter?

A: Segment number and blade diameter should be selected based on the material being cut and the required cutting finish. Lower tooth counts (e.g., 24T) are best for fast, rough cuts in wood, whereas higher tooth counts like 36T or 60T yield smoother finishes in metal or plastic.Q: Where can I purchase the thin circular saw blade and how is it packaged?

A: These blades are available through distributors, exporters, manufacturers, and suppliers across India. They can be purchased individually in blister packaging or in bulk via carton packing, ensuring safe handling and transportation.Q: What processes or features contribute to blade longevity and reduced maintenance?

A: Laser-cut technology, brazed carbide teeth, and anti-corrosion coatings work together to maximize blade lifespan. The rust-resistant and heat-tolerant features reduce wear, minimizing the frequency of blade replacement or maintenance during continuous, heavy-duty usage.Q: How do expansion slots and coatings benefit user experience?

A: Laser-cut expansion slots dampen vibration and lower noise levels, making the blade more comfortable and safer to use. Anti-corrosion and non-stick coatings ensure smoother cutting and easier blade cleaning, maintaining performance over time.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Thin Circle Saw Blade' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |