- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

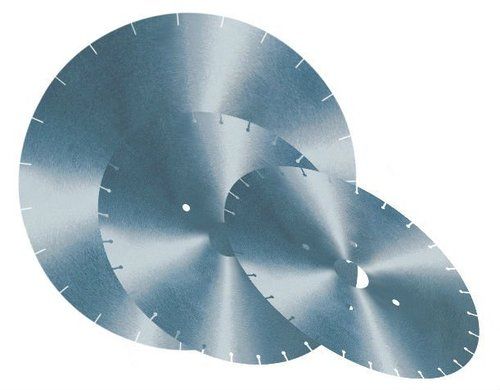

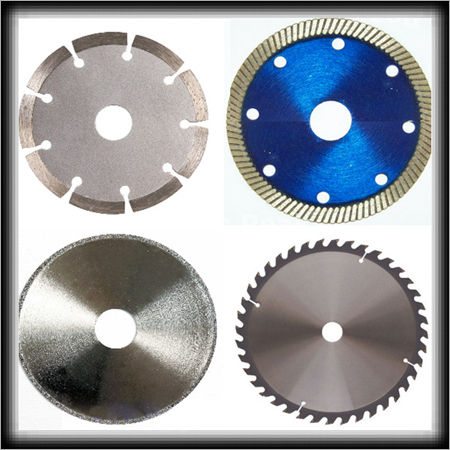

Diamond Cutting Disc

Product Details:

- Product Type Diamond Cutting Disc

- General Use For Cutting Stone, Concrete, Marble, Granite, Tiles

- Material Feature High Strength, Abrasion and Corrosion Resistant

- Type Continuous Rim/Segmented Rim

- Capacity Suitable for Wet and Dry Cutting

- Weight (kg) 0.25 kg - 0.4 kg (Depending on Size)

- Cutting Type Precision Fast Cutting

- Click to View more

X

Diamond Cutting Disc Product Specifications

- Low Vibration, Minimal Chipping, Long Life

- Anti-rust Protective Coating

- For Cutting Stone, Concrete, Marble, Granite, Tiles

- 0.25 kg - 0.4 kg (Depending on Size)

- Industrial Grade Diamond, Metal Bond

- 105 mm, 125 mm, 180 mm, 230 mm, 300 mm, 350 mm (Varies by Model)

- 1.2 mm - 3.2 mm

- W-Type, Standard Dry-Wet Slots

- 22.23 mm (Standard Size)

- Diamond Cutting Disc

- Precision Fast Cutting

- Silver/Blue

- Hot-Pressed/Brazed

- 7 mm - 10 mm

- Segmented/Continuous

- Suitable for Wet and Dry Cutting

- Continuous Rim/Segmented Rim

- High Strength, Abrasion and Corrosion Resistant

- 3.0 mm

- Adjustable, Generally 8-24

Product Description

Our organization has gained recognition as the affluent manufacturer and exporter of a qualitative range of Diamond Cutting Disc. The offered cutting disc is mainly used for precise cutting off the material much as a workshop table or radial saw cuts wood and many more under high tension. Manufactured from supreme quality raw material with the aid of sophisticated machines, these Diamond Cutting Disc are available in several sizes and specifications and can be customized as per the needs of the clients.

Feature:

- Excellent sharpening efficiency

- Rust proof

- Fine finish

- Robustness

Applications:

- for the frosted glass, ordinary flat glass, patterned glass, sandblasted glass, insulating glass, wired glass, glass tiles, polished, laminated glass, particle size between 80-120 as well as difficult to chipping, grinding smooth glass surface.

- for granite, sandstone, marble, dolomite, basalt, limestone, and other stone cutting as well as polishing, between the particle size of 36-60. Enough sharp, long working hours, fast grinding and no chipping. Smooth stone surfaces after grinding.

- for underglaze and overglaze color, blue, white and pink ancient only, sanitary ware, wall tiles, ceramic handle, floor tiles, containing silicon, silicate, and other materials. Grinding of particle size 60 to 80, short working hours, sharp and no chipping. The smooth surfaces are obtained of ceramic product after grinding.

- Varied other metal-based products can also be polished like stainless steel, aluminum, etc. The polishing of steel as well as tungsten steel, custom plated CBN sand and the CBN sharp.

Other Details:

| Name | Diamond Cutting Blades | HS code | 8202390000 |

| Process | Silvered Welded and Coppered Welded | Material | Diamond & Steel |

| Abrasive | Diamond | Packing | 1pcs / Blister |

| Size | 4",5",6",8",12',14',16',40',48' etc | OEM/ODM | Available |

| Type code | Any colour and segments sizes are available for DIY design. | ||

| Sample Cost | Depends on the sizes, please contact us to discuss further | ||

Advanced Cutting Technology

Employing hot-pressed and brazed manufacturing methods, these Diamond Cutting Discs guarantee uniform segment distribution and stable performance. The W-Type slots enhance cooling and debris removal, making them ideal for continuous heavy-duty cutting tasks. Industrial-grade diamonds embedded in a metal bond ensure abrasion and corrosion resistance.

Versatile Application

Our discs are compatible with various machines including angle grinders, marble cutters, and table saws. With blade diameters ranging from 105mm to 350mm, and teeth thickness between 1.2mm to 3.2mm, these are tailored to meet diverse project needs in the construction, masonry, and tile industries, supporting both wet and dry working conditions.

Superior Safety Features

Diamond Cutting Discs meet EN13236 safety standards, and their anti-rust protective coating increases operational reliability. The discs are designed to minimize vibration and chipping, allowing professionals to work for longer periods with reduced risk and greater comfort.

FAQs of Diamond Cutting Disc:

Q: How do I mount the Diamond Cutting Disc on my angle grinder or table saw?

A: To mount the Diamond Cutting Disc, ensure your machine is powered off and select a disc with the correct diameter and an arbor hole size of 22.23mm, which is standard for most tools. Securely attach the disc using the mounting flange, aligning the center hole, and tighten according to equipment specifications.Q: What materials can I cut using this Diamond Cutting Disc?

A: The disc is suitable for cutting a wide range of materials including stone, concrete, marble, granite, and various types of tiles. It is designed for professional use in construction, masonry, and the tile industry, and delivers precise, fast cuts with minimal chipping.Q: When is it advisable to use wet cutting versus dry cutting with this disc?

A: Wet cutting is recommended for intensive tasks or when working with thick, dense materials, as it helps cool the blade and reduce dust, prolonging disc life. Dry cutting is suitable for lighter duties or quick jobs where water supply is not available. The disc performs efficiently in both conditions.Q: Where can I source these Diamond Cutting Discs?

A: These discs are available from authorized distributors, exporters, manufacturers, and suppliers based in China. You may consult local dealers or contact the manufacturer directly for bulk purchases or export inquiries.Q: What are the benefits of using a disc with industrial-grade diamond segments and metal bond?

A: Industrial-grade diamond segments provide superior cutting efficiency and longevity, while the metal bond ensures structural integrity and resistance to abrasion and corrosion. This combination allows for low vibration cuts, minimal chipping, and extended disc lifespan.Q: What is the process for selecting the right disc size for my project?

A: Consider your equipments compatibility and the size of material to be cut. Disc diameters range from 105mm to 350mm, with corresponding teeth thickness and height. Choose larger diameters for thicker materials or heavier workloads and ensure the arbor size matches your tool.Q: How does the EN13236 safety standard enhance the usage of this product?

A: EN13236 certification confirms that the disc meets rigorous European standards for safety and reliability. Users benefit from reduced risk of disc failure during operation, ensuring safer and more consistent cutting performance on the job site.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Saw Blades' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |