- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

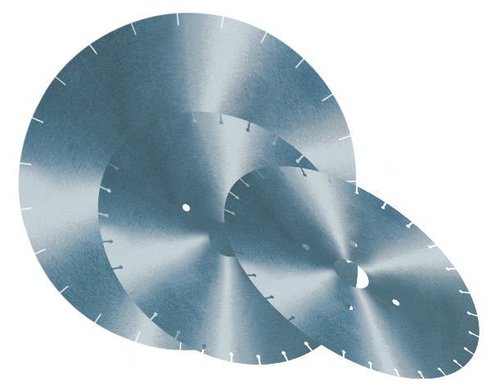

Diamond Gang Saw Blade

Product Details:

- Product Type Diamond Gang Saw Blade

- General Use Marble and Granite Cutting

- Material Feature High Wear Resistance

- Type Saw Blade

- Capacity Industrial Heavy Duty

- Weight (kg) Approx. 35-40 kg (varies by size)

- Cutting Type Wet Cutting

- Click to View more

X

Diamond Gang Saw Blade Product Specifications

- Anti-Corrosion Treated

- Diamond Gang Saw Blade

- 50 mm, 60 mm, or customized

- Standard and Silent Slot Available

- Approx. 35-40 kg (varies by size)

- Segmented Diamond

- Steel Core

- Industrial Heavy Duty

- 8-10 mm

- Diamond Bonded Alloy

- Saw Blade

- High-Frequency Sintered

- 2000 mm to 3400 mm

- Long Working Life, Smooth & Precise Cutting

- Silver with Grey Segments

- 8-10 mm

- 38-42 Segments

- 15 mm

- High Wear Resistance

- Marble and Granite Cutting

- Wet Cutting

Product Description

With the support of our competent professionals, we are capable of manufacturing, exporting and supply a wide array of Diamond Gang Saw Blade. This saw blade is used for cutting and grinding of marble, granite, tiles, wood, etc. Provided saw blade is manufactured by our dexterous team of professionals using high quality metal alloy and latest machines. Our offered saw blade is delivered to our clients only after its proper inspection on different aspects such as finish, quality etc. Further, we are offering this Diamond Gang Saw Blade in different specifications and at the economical prices to our esteemed clients

Features:

- Corrosion resistance

- Smooth and sharp edges finish

- Optimum strength

- Ductility

Engineered for Industrial Marble and Granite Processing

Our Diamond Gang Saw Blade excels at block cutting tasks in large-scale marble and granite operations. Made with premium diamond-bonded alloy and a tensioned steel core, the blade delivers consistent, high-quality cuts over extended use. The laser welded construction and silver soldering ensure segment integrity, reducing segment failure during high-duty cycles. Its robust build supports heavy loads and long operational hours, making it ideal for industrial applications.

Optimized for Performance and Durability

This saw blade is designed to maintain an optimum cutting speed between 25-30 m/s. Combined with a continuous water supply, it ensures efficient cooling for the segments. The polished, rust-resistant surface and anti-corrosion treatment further enhance blade longevity. The advanced technology and slot designs (including standard and silent) help minimize noise and vibration, contributing to a stable and precise cutting process.

Customizable to Project Requirements

The blade is available in various diameters (2000 mm to 3400 mm) and can be supplied with standard or tailored arbor sizes (50 mm, 60 mm, or custom). With segment thicknesses of 8-10 mm and heights of 15 mm, it adapts to diverse marble and granite cutting needs. Packaging and surface treatment can also be customized, ensuring safe transport and reliable storage in different environments.

FAQs of Diamond Gang Saw Blade:

Q: How should the Diamond Gang Saw Blade be used for optimal performance?

A: For best results, operate the blade at its recommended speed of 25-30 meters per second and ensure a continuous water supply to keep segments cool. Always mount the blade securely on an appropriate gang saw or frame saw machine and keep the blade free from excessive debris for clean, precise cutting.Q: What types of materials can this saw blade cut effectively?

A: This blade is specifically engineered for cutting marble and granite blocks. Its high wear-resistant, diamond-bonded alloy segments and robust steel core make it suitable for both soft and hard varieties of these stones, ensuring smooth and efficient processing.Q: When should the blade be replaced or maintained?

A: Typically, the blade lasts between 400 and 600 running hours, depending on the stone hardness and working conditions. Inspect the segments regularly for wear and cracks, and replace the blade when segment height decreases significantly or if cutting performance diminishes.Q: Where is the Diamond Gang Saw Blade manufactured and supplied?

A: The blade is manufactured in China and is available for distribution, export, and supply to industrial users worldwide. It can be delivered in a sturdy wooden case or according to customer requirements to ensure safe shipment.Q: What is the segment bonding and manufacturing process used for this blade?

A: Each segment is silver soldered onto the core and then laser welded for additional strength. High-frequency sintering technology ensures that the diamond particles are securely bonded, giving the blade its renowned cutting ability and long working life.Q: How does the blades design benefit marble and granite processing operations?

A: Thanks to its tensioned steel core, anti-corrosion coated surface, and polished finish, the blade minimizes vibration, resists rust, and delivers consistently smooth, precise cuts. These features reduce downtime and maintenance, significantly improving processing efficiency.Q: What safety measures should be followed during operation?

A: Always provide a continuous water supply to avoid overheating. Ensure that the blade is correctly tensioned on the machine, use recommended cutting speeds, and regularly check for any damage. Proper installation and regular inspections can prevent accidents and prolong blade lifespan.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

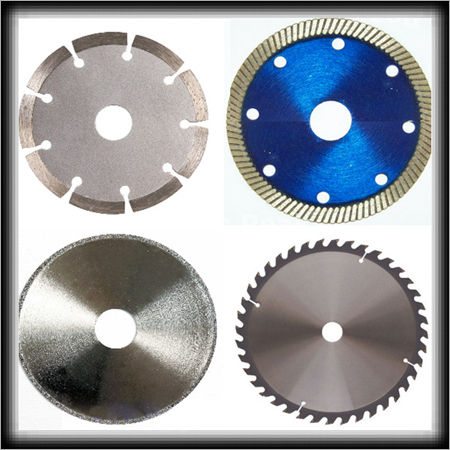

Other Products in 'Diamond Saw Blades' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |