- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

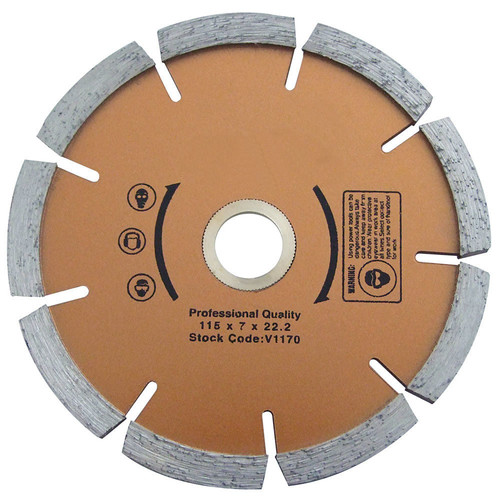

Diamond Saw Blade

Product Details:

- Product Type Diamond Saw Blade

- General Use Cutting and grinding of stone, concrete, marble, granite, tiles, and other hard materials

- Type Circular Saw Blade

- Capacity Designed for industrial and construction site usage

- Weight (kg) Approx. 1.2 kg

- Cutting Type Wet and Dry Cutting

- Arbor 22.23 mm (Standard)

- Click to View more

X

Diamond Saw Blade Product Specifications

- 350 mm

- 22.23 mm (Standard)

- Diamond Saw Blade

- 3.2 mm

- 24

- Silver with blue and red segment markings

- 3.2 mm

- Designed for industrial and construction site usage

- Laser Welding Technology

- Segmented rim with laser welded teeth

- Cutting and grinding of stone, concrete, marble, granite, tiles, and other hard materials

- Wet and Dry Cutting

- Circular Saw Blade

- 10 mm

- Approx. 1.2 kg

Product Description

We are the noteworthy manufacturer, exporter and supplier of premium quality Diamond Saw Blade. Provided saw blade is manufactured at our advanced manufacturing unit using the high grade raw material and sophisticated technology. Our offered saw blade is used for cutting and edging flat surface of frosted glass, sandblasted glass, glass, patterned glass, wired glass, insulating glass, laminated glass, glass tiles and many more. We provide this Diamond Saw Blade in various sizes specifications as per needs of our clients and at reasonable price.

Features:

- Anti-corrosive

- Sharp edges

- High strength

- Perfect finish

Other Details:

| Diamond Saw Blade | |||

| Blade Diameter(mm) | Segment Dimension(mm) | Segment No. | Application |

| 350 | 40*3.0*10 | 24 | For trimming and slabbing Concrete etc. |

| 40*3.2*15 | 24 | ||

| 400 | 40*3.4*10 | 28 | |

| 40*3.6*15 | 28 | ||

| 450 | 40*3.8*10 | 32 | |

| 40*4.0*15 | 32 | ||

| 500 | 40*3.8*10 | 36 | |

| 40*4.0*15 | 36 | ||

| 550 | 40*4.2*10 | 38 | |

| 40*4.2*15 | 38 | ||

| 600 | 40*4.6*10 | 42 | |

| 40*4.6*15 | 42 | ||

| 700 | 40*5.0*10 | 50 | |

| 40*5.0*15 | 50 | ||

| 800 | 40*5.5*10 | 57 | |

| 40*5.5*15 | 57 | ||

| 900 | 23*6.6/6.0*13 | 64 | |

| 1000 | 23*7/6.4*13 | 70 | |

| 1200 | 23*7.5/6.9*13 | 80 | |

| 1300 | 23*8/7.4*13 | 88 | |

| 1400 | 23*8.4/7.8*13 | 92 | |

| 1600 | 23*9.0/8.4*13 | 108 | |

| 1600 | 23*9.2/8.4*15 | 108 | |

| 1800 | 24*10/9.2*15 | 120 | |

| 2000 | 24*10.4/9.6*15 | 128 | |

| 2200 | 24*11.5/10.5*15 | 132 | |

| 2500 | 24*11.5/10.5*15 | 140 | |

| 3000 | 24*13/12*20 | 160 | |

Advanced Segmentation for Superior Cutting

This diamond saw blade is equipped with 24 segmented, laser-welded teeth, maximizing both longevity and cutting efficiency. The 3.2 mm teeth thickness and 10 mm height are specifically designed to tackle tough materials without compromising on speed or accuracy. Laser welding fortifies tooth attachment, reducing the risk of segment dislodgement during heavy-duty applications.

Innovative Slot Design for Noise Reduction

The blade integrates a unique slot design that disperses cutting vibrations and significantly lowers operating noise. This feature not only makes the cutting process more comfortable but also extends the blades lifespan and ensures more precise, clean cuts on every use.

Versatile for Wet and Dry Operations

Engineered for versatility, this blade efficiently handles both wet and dry cutting tasks, giving operators the flexibility to work in different environments. Its robust construction ensures excellent performance whether used with water cooling for reduced dust and heat or dry for speedy, convenient usage.

FAQs of Diamond Saw Blade:

Q: How do I properly use the diamond saw blade for both wet and dry applications?

A: For wet cutting, ensure a consistent water supply to cool the blade and control dust levels. For dry cutting, allow adequate air flow and avoid continuous use to prevent overheating. Always follow the manufacturers safety guidelines to maximize blade life and safety.Q: What types of materials can I cut with this diamond saw blade?

A: This blade is ideal for cutting stone, concrete, marble, granite, tiles, and other similar hard materials. Its segmented laser-welded teeth and robust build make it suitable for both construction and industrial applications.Q: When should I replace the diamond saw blade?

A: Replace the blade when you notice decreased cutting performance, visible wear on segment height, or signs of blade damage such as warping or missing teeth. Regular inspection before use helps maintain optimal safety and results.Q: Where can the diamond saw blade be used?

A: The blade is designed for use on construction sites, in industrial workshops, and with compatible masonry saws, tile saws, or handheld cutting machines. Its standard 22.23 mm arbor fits most professional-grade tools.Q: What is the process for safe installation and operation of the blade?

A: First, power off and disconnect the machine. Securely mount the blade onto a clean, compatible arbor (22.23 mm). Check for tightness and correct rotation. Wear appropriate personal protective equipment (PPE), such as goggles and gloves, and always follow the equipments operational manual and ISO 9001:2015 safety guidelines.Q: How does the slot design benefit cutting operations?

A: The dedicated slot design greatly reduces vibrations and noise generated during cutting, resulting in a smoother operation, less fatigue for the user, and finer finish on the workpiece. It also helps extend the lifespan of both blade and equipment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Saw Blades' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |