- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

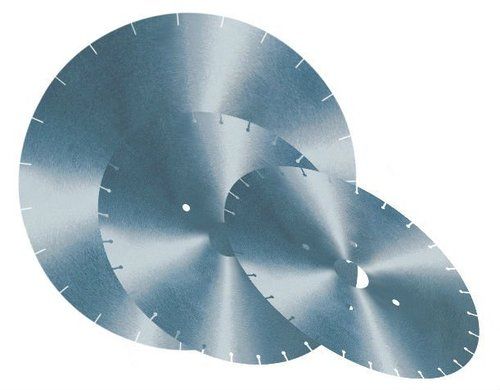

Laser Circular Saw Blades

Product Details:

- Product Type Laser Circular Saw Blade

- General Use Precision cutting of wood, metal, plastic, and other materials

- Material Feature High-grade industrial carbide-tipped steel

- Type Laser Cut Circular Saw

- Capacity Up to 7500 RPM

- Weight (kg) 1.25 kg

- Cutting Type Clean, fast, and fine cutting

- Click to View more

X

Laser Circular Saw Blades Product Specifications

- Alternate Top Bevel (ATB)

- 355 mm

- Laser cutting and precision balancing

- Tungsten carbide

- 1.25 kg

- Laser Cut Circular Saw

- Up to 7500 RPM

- Silver with black laser markings

- 25.4 mm (1 inch)

- Clean, fast, and fine cutting

- 2.8 mm

- Laser Circular Saw Blade

- Laser cut expansion slots for reduced vibration and heat

- Laser-cut anti-vibration slots

- 2.8 mm

- Precision cutting of wood, metal, plastic, and other materials

- Non-stick corrosion-resistant finish

- 36

- High-grade industrial carbide-tipped steel

- 12 mm

Product Description

Laser Circular Saw Blades are welded blades which we manufacture and export for various diamond cutting purposes. These are available in various sizes of 4",5",6",8",12 14 16...40,48etc. The segment sizes and colors can also be made to order according to the requirements of the clients. Laser Circular Saw Blades cuts the diamond as radial saw cuts wood. These blades cut different diamond grits and are known for their optimum quality and cost- effectiveness.

Special Attractions:

- These are used in precision diamond cutting

- These are very sharp and have longer working life

- Supreme grade material which is of highest quality is utilized

- Known for their functional efficiency and rugged design

- Corrosion resistance is one of their striking features

- Outstanding quality is assured, as we believe in customer satisfaction

- Quality inspectors ensure international standards are maintained at very stage of production

Precision Performance Across Applications

Engineered for diverse cutting environments, these laser circular saw blades handle wood, metal, plastics, and composite materials with ease. The dynamically balanced construction ensures vibration-free, accurate cuts, delivering consistently smooth finishes. Whether for industrial production or precision joinery, their versatility and reliability mark them as indispensable tools.

Enhanced Safety and Reduced Noise

With advanced laser-cut slots, our blades substantially reduce both vibration and noise during operation. This innovation not only creates a quieter work environment but also extends the blades life by minimizing heat buildup, promoting cooler, safer, and more efficient cutting even under demanding conditions.

Built for Longevity and Compatibility

Crafted from high-grade carbide-tipped steel, these blades resist impact and wear, providing an extended operational lifespan. Compatible with most standard industrial and portable saws, installation is simplified by the 25.4 mm bore diameter. Black laser markings and corrosion-resistant coating further ensure lasting performance and easy maintenance.

FAQs of Laser Circular Saw Blades:

Q: How do laser-cut slots in these circular saw blades benefit my cutting applications?

A: Laser-cut expansion slots minimize vibration and noise while reducing heat buildup. This enables cooler operation, prolongs blade life, and delivers smoother, cleaner cuts across wood, metal, plastics, and composite materials.Q: What materials can I cut using this laser circular saw blade?

A: This blade is engineered for a wide spectrum of materialswood, metals, plastics, and composite materials. Its high-grade tungsten carbide teeth and ATB configuration ensure precise, efficient cutting in various workshop or industrial applications.Q: When is it appropriate to use this circular saw blade in my projects?

A: Deploy this blade when precision and clean finishes are needed, or when working with challenging materials like metals or composites. It excels in both high-volume industrial fabrication and detailed craftsmanship projects, tolerating up to 7500 RPM.Q: Where can I use these laser circular saw blades?

A: Designed for compatibility, these blades fit most industrial and portable circular saws with a 25.4 mm bore diameter. Suitable for factories, construction sites, woodworking shops, or any location requiring precise and dependable cutting tools.Q: What is the process for maintaining these saw blades?

A: Regularly clean the blade with a non-abrasive cleaner, inspect for signs of wear or damage, and ensure the teeth remain sharp. The corrosion-resistant, non-stick coating simplifies cleaning and helps maintain smooth cutting performance.Q: How does the blade ensure precision and safety during use?

A: Precision engineering, laser balancing, and ATB teeth deliver accurate cuts with minimal vibration. Laser-cut slots reduce heat and noise, safeguarding both the blade and the operator for consistent, safe operation.Q: What are the main benefits of using these blades over standard saw blades?

A: These laser-cut blades provide faster, cleaner cuts, less noise, reduced heat, and greater durability. Their premium carbide-tipped steel and anti-corrosion coating offer a longer lifespan and smoother operation compared to conventional saw blades.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Saw Blades' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |