- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

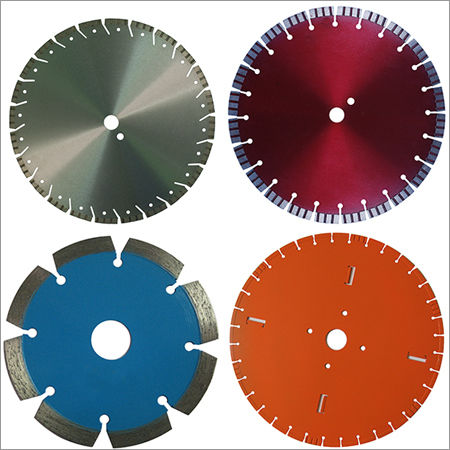

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

Diamond Cutting Segments

Product Details:

- Product Type Diamond Cutting Segments

- General Use Stone, Concrete, Granite, and Marble Cutting

- Material Diamond and Metal Alloy Bond

- Type Segmented

- Capacity High Performance

- Cutting Speed Fast/High Efficiency

- Cutter Type Diamond Saw Blade Segment

- Click to View more

X

Diamond Cutting Segments Price And Quantity

Diamond Cutting Segments Product Specifications

- Manual/Electric Saw Compatible

- Diamond Saw Blade Segment

- Regular, Sandwich, Turbo

- Silver/Grey

- Segmented

- High Performance

- Standard/Grooved

- Standard/Custom (40mm x 3.2mm x 10mm Example)

- Diamond and Metal Alloy Bond

- Fast/High Efficiency

- Segmented Teeth

- Stone, Concrete, Granite, and Marble Cutting

- Long Life, Fast Cutting, Stable Performance

- Diamond Cutting Segments

Product Description

With sound infrastructural facilities, we bring forth for our customers a comprehensive range of Diamond Cutting Segments. Stringent quality tests are conducted on these segments by our team of quality controllers, before delivering to the clients. Our range is highly demanded in the market for its smooth operation, high cutting speed and longer functional life. Diamond Segments are widely being used for cutting limestone, granite, asphalt and marbles. We offer these segments in various sizes, diameters and thickness.

Special Attractions:

- Appreciated for their longer working life and negligible maintenance

- Acknowledged by clients as these are easy to use

- Popular among clients for their feature of corrosion resistance

- Preferred for their rugged design

- Modern machinery and tools are used by our experienced engineers

- We never compromise on quality and maintain international quality standards

- Have high tensile strength

- These are available at industry leading prices

|

Product Detail: |

|

|

Product Name: |

Diamond Segments |

|

Product Code: |

SPT03 |

|

Brand Name: |

SHINE PEAK DIAMOND |

|

Model Number: |

SHINE PEAK - SPT03 |

|

Certification: |

ISO9002 |

|

Condition : |

New |

|

Business type |

Manufacturer, Exporter and Supplier |

|

Payment Terms : |

T/T or L/C any payment can be possible |

|

Price: |

USD/EURO/RMB |

|

Warranty: |

6 month |

|

Material / Metal Processed |

Diamond & Alloy Steel |

|

Monthly Production Capacity: |

10 Pieces |

|

|

|

|

Machine Technical Specification: |

|

|

Dimension / Standard Size Range: |

Different size are available upon request |

|

Raw Material: |

Diamond & Alloy Steel |

|

Use / Application: |

Diamond Segment for diamond saw blade |

|

Finishing: |

Painted / Ti-coated |

|

Color: |

any color and Up to Client requirement |

|

Quality: |

Professional |

|

Extra Services: |

OEM Service and Custom |

|

|

|

|

Packaging & Delivery Detail: |

|

|

Packaging Detail: |

As per international standard |

|

Delivery Detail: |

20 to 30 in working days |

|

Shipment By: |

Sea, Air, Road Transportation |

Versatile Applications for Hard Materials

Ideal for cutting granite, marble, stone, and concrete, these diamond segments are expertly engineered for compatibility with a range of machines, including bridge cutters, edge cutting machines, and circular saws. Whether your project calls for wet or dry cutting, these segments adapt seamlessly to your needs, supporting both smooth and rough surface finishes.

Precision Bond and Longevity

The metal bond ensures strong adhesion of industrial-grade diamonds, offering high durability and resistance to wear, even when tackling hard stones. With a choice of segment heights10mm, 12mm, and 15mmand customizable grit size, users enjoy extended tool life and dependable high-speed performance with every cut.

Tailored Performance and Easy Integration

Available in multiple segment types such as regular, sandwich, turbo, and grooved slots, these diamond segments suit diverse cutting demands. Supplied in secure box or paper packing, they integrate effortlessly into standard and custom-sized saws. Both OEM and standard options allow distributors, exporters, manufacturers, and suppliers to fulfill unique project needs efficiently.

FAQs of Diamond Cutting Segments:

Q: How are metal bond diamond cutting segments used for different applications?

A: Metal bond diamond cutting segments are versatile and can be used for both wet and dry cutting tasks on hard materials such as granite, marble, stone, and concrete. The choice of segment type, grit size, and machine compatibility allows users to select the optimum configuration for surface finishingbe it smooth or roughensuring the highest efficiency and desired results.Q: What makes these diamond cutting segments suitable for hard stone and concrete?

A: These segments are manufactured using a robust diamond and metal alloy bond, providing exceptional hardness and wear resistance. Their design ensures stable performance and long service life, making them ideal for cutting hard stones and concrete with high efficiency and minimal segment wear.Q: When is it necessary to choose a particular segment height or grit size?

A: Select segment height (10mm, 12mm, or 15mm) and grit size based on your cutting depth requirements and the desired finish. Coarse grit is suitable for rapid, aggressive cuts, while fine grit delivers smoother finishes. Higher segment heights extend tool life, especially in demanding, high-volume cutting operations.Q: Where can these diamond cutting segments be installed and what machines are compatible?

A: They are designed for installation on bridge cutters, edge cutting machines, and circular saws. The segments support both manual and electric saws, providing flexibility across a variety of stone fabrication and construction environments.Q: What is the process of ordering custom-sized or OEM diamond segments?

A: To order custom-sized or OEM diamond cutting segments, simply provide your dimensional and performance specifications (such as segment size, height, type, and grit). The manufacturer can then tailor the product to your application, ensuring optimal results and machine compatibility.Q: What are the primary benefits of using these high-performance segments?

A: Key benefits include fast and efficient cutting, extended service life, stable and consistent performance, and adaptability to different materials and machines. This not only boosts productivity but also reduces replacement frequency and operational costs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cutting Tools ' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |