- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

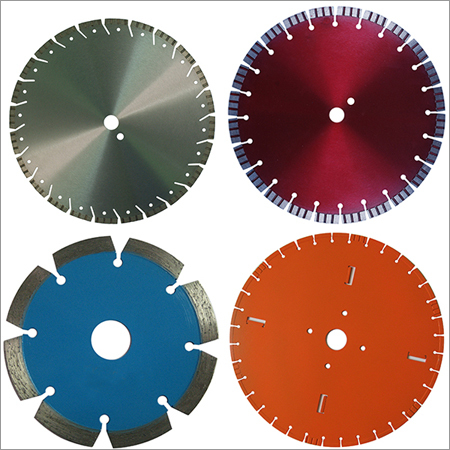

Electroplated Diamond Tools

Product Details:

- Product Type Electroplated Diamond Tools

- General Use Industrial Material Cutting, Grinding and Shaping

- Material Steel Body with Electroplated Diamond Coating

- Type Cutting / Grinding Tools

- Capacity Varies by Tool Type

- Weight (kg) 0.15 - 2.5 kg (Depending on Tool Size)

- Cutting Speed Up to 3800 RPM

- Click to View more

X

Electroplated Diamond Tools Price And Quantity

Electroplated Diamond Tools Product Specifications

- High Precision, Long Life, Sharpness Retention, Versatile Applications

- Industrial Material Cutting, Grinding and Shaping

- 0.5 mm to 10 mm

- 50 mm to 400 mm Diameter (Available)

- Varies by Tool Type

- Custom Slotting

- Up to 3800 RPM

- Silver Metallic with Diamond Coating

- Steel Body with Electroplated Diamond Coating

- Manual / Machine Driven

- Cutting / Grinding Tools

- Electroplated Diamond Tools

- 0.15 - 2.5 kg (Depending on Tool Size)

- Diamond Grit Embedded

- Custom / As Required

- N/A (Hand Tools), 220V-415V (Machine Tools)

- Fine / Coarse (Based on Grit)

- Continuous Rim / Segmented

Product Description

Our clients can avail from us an ultimate range of Electroplated Diamond Tools. The offered tools are manufactured at our modern manufacturing unit using premium quality raw material with the aid of advanced manufacturing techniques. Provided tools are widely used for cutting and grinding applications of hard material surface and are stringently tested on various parameters for assurance of their perfection. Clients can avail these Electroplated Diamond Tools from us in different sizes and specifications as per their needs.

Features:

-

Accurate dimension

-

Precise and high cutting speed

-

Corrosion resistance

-

Flawless finish

Advanced Electroplated Bond Technology

These diamond tools use a single-layer electroplated bond, ensuring uniform grit distribution for precision and longevity. The diamond coating (0.10.3 mm thickness) delivers consistent performance in all cutting and grinding scenarios, maintaining sharpness even during extended industrial use.

Versatile Application Area

Suitable for sectors such as glass processing, stone sculpting, ceramic shaping, fiberglass trimming, and hardened steel fabrication. Various shapes and custom sizes, segment types, teeth designs, and slotting options are available for tailored solutions that match specific workplace requirements.

Optimized Performance Under Demanding Conditions

Electroplated diamond tools offer fine or extra-fine finishes, rapid cutting speeds, and can be used in wet or dry conditions up to 180C. With a life expectancy up to twice as long as conventional tools, users benefit from lower replacement frequency and improved efficiency, even in high intensity projects.

FAQs of Electroplated Diamond Tools:

Q: How are electroplated diamond tools different from conventional abrasive tools?

A: Electroplated diamond tools feature a single diamond grit layer bonded directly to a steel body, offering greater sharpness, better precision, and up to twice the service life when compared to conventional abrasive tools. This design also enables superior surface finishes and reduced tool wear.Q: What materials can be processed using these diamond tools?

A: These tools are engineered for industrial use in cutting, grinding, and shaping materials such as glass, stone, ceramics, fiberglass, and hardened steel. They are also adaptable for use on other hard or brittle materials as required.Q: When should I use wet versus dry cutting or grinding with these tools?

A: Wet use is recommended for reducing heat buildup, prolonging tool lifespan, and minimizing dust while working with materials that are prone to thermal damage. Dry use is suitable when coolant is unavailable, but operating within the maximum temperature threshold (up to 180C) is essential to maintain tool performance.Q: Where can I purchase or source these electroplated diamond tools in India?

A: Electroplated diamond tools are available from local distributors, exporters, manufacturers, and suppliers throughout India. Custom specifications can typically be fulfilled by contacting these vendors directly and specifying requirements such as shape, size, segment type, and grit size.Q: What is the process behind manufacturing these diamond tools?

A: Electroplated diamond tools are produced using a method where diamond abrasive grits are uniformly bonded onto the surface of a steel body via electroplating. This process creates a highly consistent abrasive layer that optimizes tool life, sharpness, and overall performance during use.Q: How should these tools be used for maximum efficiency and longevity?

A: To maximize efficiency and tool longevity, ensure the correct grit size and shape are selected for the material and application. Operating at recommended cutting speeds (up to 3800 RPM) and adhering to wet/dry usage guidelines helps maintain sharpness, avoid overheating, and extends the life expectancy.Q: What benefits do electroplated diamond tools offer in industrial material processing?

A: Key benefits include high precision cutting and grinding, long-lasting sharpness, versatility across varied materials and shapes, fine to extra-fine surface finish capabilities, rapid operational speeds, and a lifespan that is up to twice longer than conventional abrasive tools.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cutting Tools ' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |