- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

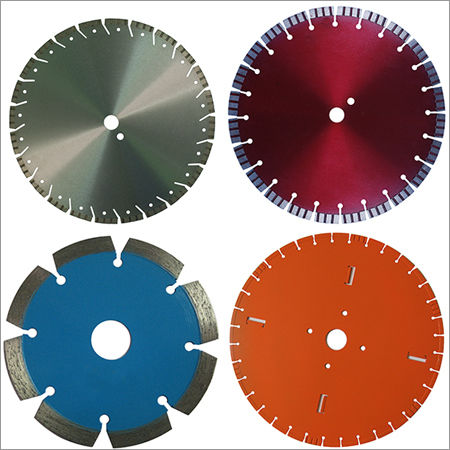

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

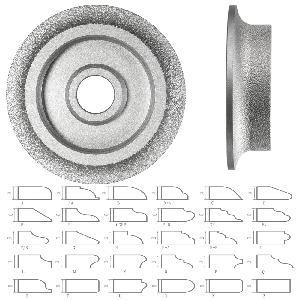

Vacuum Brazed Diamond Tool

Product Details:

- Product Type Vacuum Brazed Diamond Tool

- General Use Cutting, Grinding, Polishing hard materials like granite, marble, concrete

- Material Steel Body with Industrial Grade Diamond Grits

- Type Segmented/Brazed

- Capacity Heavy Duty Professional Use

- Weight (kg) 0.5 - 1.2

- Cutting Speed High Speed (8000 - 15000 RPM)

- Click to View more

X

Vacuum Brazed Diamond Tool Price And Quantity

Vacuum Brazed Diamond Tool Product Specifications

- Circular/Disc Type

- Fast Cutting, Long Life, No Water Required

- Varies by Size (commonly 7-12)

- 1.5 - 4 mm

- 0.5 - 1.2

- Heavy Duty Professional Use

- Cutting, Grinding, Polishing hard materials like granite, marble, concrete

- 4, 5, 6 (100mm, 125mm, 150mm)

- Vacuum Brazed Diamond Tool

- Electric or Pneumatic

- Steel Body with Industrial Grade Diamond Grits

- Segmented/Brazed

- Standard Slot

- 110V/220V (tool-dependent)

- High Speed (8000 - 15000 RPM)

- Vacuum Brazed Continuous/Segmented

- Silver/Metallic with Diamond Shine

- Diamond Grit Teeth

Product Description

Assisted by a qualified workforce and advanced manufacturing unit, we are engaged in offering a wide range of Vacuum Brazed Diamond Tool. The offered diamond tool is manufactured with the help of sophisticated machinery using high grade raw material procured from reliable vendors of the market. It is mainly used for grinding various hard non-ferrous material like marble granite, glass, and ceramic, hard concrete, brick and many more. Clients can avail this Vacuum Brazed Diamond Tool in various sizes and specifications as per their needs at economical prices.

Features:

- Simple to fit

- Dimensional accuracy

- Precisely designed

- Flawless finish

Applications: Appropriate for grinding a variety of hard Non-ferrous materials like glass, marble granite, and ceramic, brick and hard concrete. Superiorities of vacuum brazed tech:

- Excellent coherence: It comes with strong and good coherence property depending on the chemical metallurgical effects on abrasives, brazing filler matrix and metal interface when the temperature is high of brazing. It is enough to manage the abrasive particles tightly in the advanced grinding even on hard wearing with the width of the brazed filler metal on 20-30 percent of the abrasives.

- Better abrasive convexity: Usually the convexity height of abrasives can reach 70-80 percent due to which the tools will be sharper. The grinding force as well as temperature will be actually decreased.

- Enough place for scraps: It is sufficient for the high abrasive convexity and not easier to be blocked during grinding to avoid the tool failure.

- Less waste of the diamond: In the process of brazed diamond tools, excluding the rarely abrasive fall off, most of them can be utilized to the height of 70-80 percent of itself.

- Cut granites, rebars, concretes, glass, ceramics, woods, plastics, etc. with high efficacy.

- Strong structure: It can be easily and safely used in the super-speed of 300-500 meters per seconds to 1000 meters per seconds.

- Eco friendly: It systematically breaks away from the blocks of severe pollution with the electroplating designed from super hard abrasive tools replaced by high temperature brazing which reached the standards of Green cleaning manufacturing.

- The best production equipment, raw materials as well as advanced manufacturing technology is used that can be produced efficiently, and steadily.

Other Details:

|

Name |

Diamond Profile Wheels |

HS code |

8202390000 |

|

Process |

Brazed |

Material |

Steel Base and Diamond |

|

Abrasive |

Diamond |

Packing |

Paper Box |

|

Size |

20mm-100mm,etc |

OEM/ODM |

Available |

|

Type code |

Any colour and sizes are available for DIY design. |

||

|

Sample Cost |

Depends on the sizes, please contact us to discuss further |

||

Advanced Vacuum Brazed Technology

Our diamond tools employ a vacuum brazed bonding process, creating an exceptionally strong mechanical bond between diamond grits and the steel substrate. This ensures extended durability even when used for cutting and grinding the toughest materials, contributing to the tools long service life and consistent performance.

Versatile Application Across Hard Materials

Carefully engineered for professional use, these tools are suitable for a range of challenging materials including granite, marble, concrete, stone, refractory, and brick. Whether cutting, grinding, or polishing, expect precise results with minimal chipping and a superior surface finish every time.

FAQs of Vacuum Brazed Diamond Tool:

Q: How does the vacuum brazed bonding method enhance the durability of the diamond tool?

A: The vacuum brazed method forms a strong mechanical bond between the steel body and industrial-grade diamond grits, significantly improving resistance to wear, heat, and mechanical stress. This process enhances the tools durability and extends its effective cutting and grinding lifespan.Q: What types of materials can this diamond tool process effectively?

A: This tool is designed for heavy-duty cutting, grinding, and polishing of hard materials such as stone, masonry, concrete, tile, refractory, and brick. It produces smooth, precise finishes and operates with minimal chipping, making it suitable for professional applications across various industries.Q: When should I use this tool for wet or dry operations?

A: You can use this diamond tool for both wet and dry operations according to your projects requirements. No water is strictly required due to its robust design and heat tolerance up to 600C, but wet cutting can be beneficial for dust control or added cooling when preferred.Q: Where can this diamond tool be used and what equipment is it compatible with?

A: The tool is compatible with angle grinders, hand grinders, and cut-off saws, and suitable for both on-site construction and workshop environments. It fits arbors of 16mm, 20mm, or 22.23mm, depending on the specific tool size.Q: What benefits does the coarse (30/40 grit) and multi-grit options provide?

A: Coarse grit (30/40) and available multi-grit options allow for fast material removal and tailored surface finishes. Users can select the appropriate grit based on specific cutting, grinding, or polishing needs, achieving optimal speed and finish quality.Q: How does the manufacturing standard improve performance and reliability?

A: Manufactured in China under ISO 9001:2015 certification, these diamond tools follow strict quality controls, resulting in stable, high-speed operation (800015,000 RPM), low to medium noise levels, precise cutting thickness, and reliable service life up to 5000 meters of linear cut, depending on the material.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cutting Tools ' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |