- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

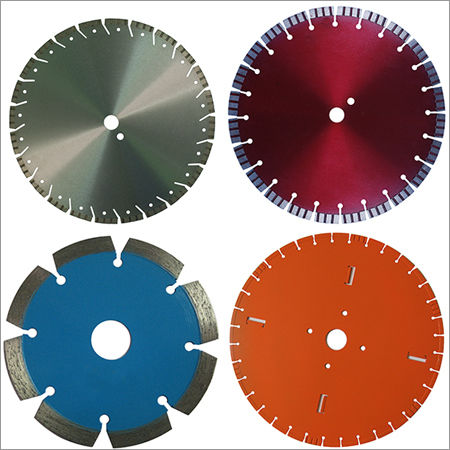

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

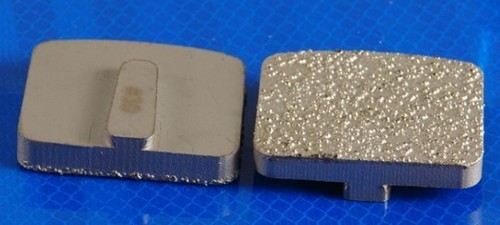

Vacuumed Diamond Plates

Product Details:

- Product Type Vacuumed Diamond Plate

- General Use Cutting, Grinding, Polishing

- Material High-grade Diamond Alloy

- Type Segmented Diamond Plate

- Capacity Industrial Heavy Duty

- Weight (kg) 2.5

- Cutting Speed High Speed (up to 11000 RPM)

- Click to View more

X

Vacuumed Diamond Plates Product Specifications

- 12

- Silver/Grey

- 350 mm

- Wet & Dry Cutter

- Enhanced Durability, Fast Cutting, Heat Resistance

- Segmented Diamond Plate

- High Speed (up to 11000 RPM)

- 220V

- 1.2 mm to 4 mm

- 2.5

- Diamond Teeth

- Standard Laser Slot

- Industrial Heavy Duty

- Electric

- Vacuumed Diamond Plate

- Vacuum Brazed Segment

- Cutting, Grinding, Polishing

- High-grade Diamond Alloy

Product Description

We are a trusted enterprise, successfully engaged in manufacturing, exporting and supplying a wide range of Vacuumed Diamond Plates. Our experienced professionals manufacture these plates with the aid of contemporary techniques in accordance with industrial standards. Also, checked by our quality professionals on several aspects, these plates are widely used for surface grinding applications. In addition, interested clients can purchase these Vacuumed Diamond Plates at marginal prices from us.

Features:

- High impact resistance

- Robust construction

- Premium finish

- Compact size

Advanced Vacuum Brazed Technology

Utilizing vacuum brazed technology ensures the diamond segments are firmly anchored to the plate, providing extended tool life, exceptional cutting accuracy, and minimized segment loss. This manufacturing process is pivotal for achieving optimal performance in demanding, industrial environments.

Universal Compatibility and Ease of Use

With a standard arbor size of 25.4 mm, these diamond plates are engineered to fit all major machine brands without modification. Their universal design ensures seamless integration into existing equipment, making them an excellent choice for distributors, exporters, and end-users alike.

Superior Performance and Safety

Designed for both wet and dry cutting, these plates offer low noise output (< 80 dB), high-speed capabilities, and optimized extraction slots for effective dust minimization. The combination of high-grade diamond alloy and optimized bond enhances durability and contributes to a safer, cleaner work environment.

FAQs of Vacuumed Diamond Plates:

Q: How can I install the vacuumed diamond plate on my cutting or grinding machine?

A: The vacuumed diamond plate features a universal 25.4 mm arbor size, making it compatible with all standard electric machine brands. Simply align the plate with your machines arbor and securely tighten it following your equipments standard installation procedure.Q: What applications are suitable for this segmented diamond plate?

A: These plates are ideal for cutting, grinding, and polishing surfaces such as concrete, granite, marble, and ceramic. Their industrial heavy-duty build and fast cutting speed make them suitable for professional construction, remodeling, and fabrication projects.Q: When should I use water-assisted cooling versus air cooling?

A: For demanding or continuous operations, especially on dense materials like granite, water-assisted cooling is recommended for optimal performance and to prolong the tools service life. Air cooling is sufficient for lighter jobs and situations where water usage is impractical.Q: Where is this diamond plate manufactured and distributed from?

A: The vacuumed diamond plates are manufactured in China and are available through distributors, exporters, suppliers, and manufacturers worldwide. This ensures global availability and support for customers in different regions.Q: What process ensures the durability and high performance of these diamond plates?

A: The plates are produced using vacuum brazed technology which securely affixes the diamond segments to the metal body. This process enhances cutting efficiency, prolongs service life, and improves overall safety during use.Q: How does this product minimize dust during cutting or grinding?

A: The segmented plate incorporates optimized extraction slots designed to maximize dust removal during use. This feature helps maintain cleaner workspaces and contributes to a healthier working environment.Q: What benefits does this diamond plate offer over conventional options?

A: Offering enhanced durability, high-speed cutting, advanced heat resistance, corrosion resilience, and low noise operation, these plates outperform many traditional options. Their compatibility with multiple machines and ability to handle wet or dry tasks further enhance their value for industrial users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cutting Tools ' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |