- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

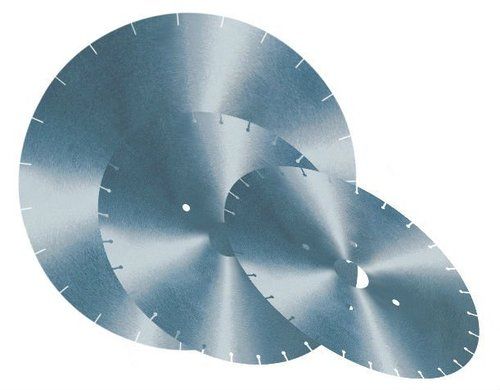

Silver Brazed Diamond Saw Blades

Product Details:

- Product Type Silver Brazed Diamond Saw Blade

- General Use Cutting Concrete, Marble, Granite, and Stone

- Material Feature High Hardness, Wear Resistance

- Type Segmented Diamond Blade

- Capacity Heavy Duty Cutting

- Cutting Type Wet and Dry Cutting

- Arbor Standard (as per disc diameter), e.g., 25.4 mm

- Click to View more

X

Silver Brazed Diamond Saw Blades Product Specifications

- Industrial Grade Diamond, Metal Bond Matrix

- Wet and Dry Cutting

- Silver Brazed Segment Technology

- Standard Expansion Slots

- Standard (as per disc diameter), e.g., 25.4 mm

- Heavy Duty Cutting

- Segmented Diamond Blade

- Segmented

- Silver Brazed Diamond Saw Blade

- Fast Cutting, Long Service Life, High Precision

- High Hardness, Wear Resistance

- Cutting Concrete, Marble, Granite, and Stone

- 105 mm, 125 mm, 180 mm, 230 mm, 250 mm, 300 mm, 350 mm, 400 mm

- Silver Body with Diamond Segments

Product Description

We have marked our prominence as one of the distinguished manufacturers, suppliers and exporters of qualitative gamut of Silver Brazed Diamond Saw Blades. These blades are designed using superior grade raw materials, which imparts them high strength and longer functional life. Our range is highly demanded in the market for its rugged design, superior functionality and high impact, corrosion & abrasion resistance. Silver Brazed Diamond Saw Blades are extensively being used in various industries for cutting marble, granite and refractory material.

Special Attractions:

- These are available in various sizes, designs and can be customized according to your requirements

- Our knowledgeable professionals use latest techniques and machines during manufacturing

- Highest grade raw materials are used during manufacturing of these blades

- International quality standards are maintained which is ensured by our quality team

- Acknowledged by our clients for their features like unmatched performance and rugged design

- Known for corrosion resistance and negligible maintenance

- Clients can get these at rock bottom prices

| Product Detail: | |

| Product Name: | Silver Brazed Diamond Saw Blades |

| Product Code: | SPT602 |

| Brand Name: | SHINE PEAK DIAMOND |

| Model Number: | SHINE PEAK - SPT507 |

| Certification: | ISO9002 |

| Condition : | New |

| Business type | Manufacturer, Exporter and Supplier |

| Payment Terms : | T/T or L/C any payment can be possible |

| Price: | USD/EURO/RMB |

| Warranty: | 6 month |

| Material / Metal Processed | Diamond & Alloy Steel |

| Monthly Production Capacity: | 10 Pieces |

| Machine Technical Specification: | |

| Dimension / Standard Size Range: | 4"-64" |

| Raw Material: | Diamond & Alloy Steel |

| Use / Application: | Diamond Cutting for giving proper shape |

| Finishing: | Painted / Ti-coated |

| Color | any color and Up to Client requirement |

| Quality: | Professional |

| Extra Services: | OEM Service and Custom |

| Packaging & Delivery Detail: | |

| Packaging Detail: | As per international standard |

| Delivery Detail: | 20 to 30 in working days |

| Shipment By: | Sea, Air, Road Transportation |

Optimized for Professional Cutting

Designed for construction, stonework, and civil engineering, Silver Brazed Diamond Saw Blades deliver superior performance in heavy-duty environments. Their segmented design ensures rapid debris removal, fast cutting speeds, and minimal downtime. These blades excel in cutting hard materials like granite, marble, and reinforced concrete, making them indispensable for professionals seeking precision and efficiency.

Advanced Manufacturing and Safety Compliance

Produced through precision silver brazed segment technology, each blade provides secure diamond segment attachment and enhanced service life. Compliant with EN13236 Safety Standards, they ensure reliable operation at high speeds. The metal bond matrix resists wear even at temperatures reaching 600C, maintaining consistent cutting power session after session.

FAQs of Silver Brazed Diamond Saw Blades:

Q: How should I select the appropriate disc diameter for my project?

A: Choose the disc diameter based on your cutting depth requirements and machine compatibility. For cutting depths up to 120 mm, larger diameters like 350 mm or 400 mm are ideal. Ensure your angle grinder, circular saw, or table saw accommodates the selected blade size and arbor diameter.Q: What materials can be effectively cut with these diamond saw blades?

A: These segmented diamond blades are engineered for cutting a variety of hard materials including concrete, marble, granite, and various stone types commonly found in construction and civil engineering projects.Q: When is it recommended to use wet cutting versus dry cutting with these blades?

A: Both wet and dry cutting are supported. For extended service life and reduced dust, wet cutting is advisable, especially during long or intensive jobs. Dry cutting provides greater flexibility for quick or mobile tasks where water is unavailable.Q: Where are these blades typically used in the construction and stone industries?

A: They are commonly utilized on worksites involving structural concrete work, pavement cutting, stone fabrication, and tile installation. Their high precision and robust design make them suitable for both indoor and outdoor cutting tasks.Q: What is the process behind the silver brazed manufacturing method?

A: Silver brazing involves securely bonding diamond segments to the blade body using a high-temperature silver alloy. This method provides superior segment retention and supports heavy-duty, high-speed operation, ensuring reliability in demanding environments.Q: How does the blade design contribute to safety and reduced noise?

A: Each blade features a low vibration design and standard expansion slots, minimizing operational noise and enhancing stability during high-speed use. Additionally, compliance with EN13236 Safety Standards ensures safe performance on compatible power tools.Q: What are the primary benefits of using these silver brazed diamond saw blades?

A: Key advantages include fast and precise cutting, long service life, high hardness, wear resistance, and versatile compatibility with multiple tools. The blades are easy to install, available in various sizes, and are supplied in individual boxes or bulk cartons to suit distributor, exporter, or supplier needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Saw Blades' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |