- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

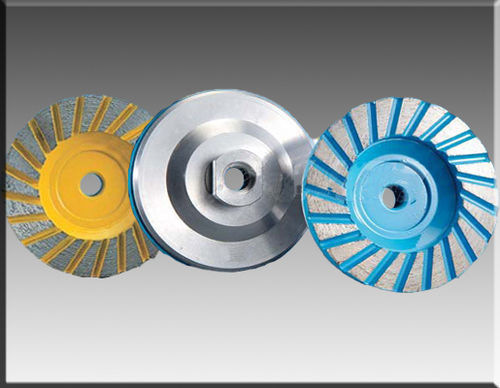

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

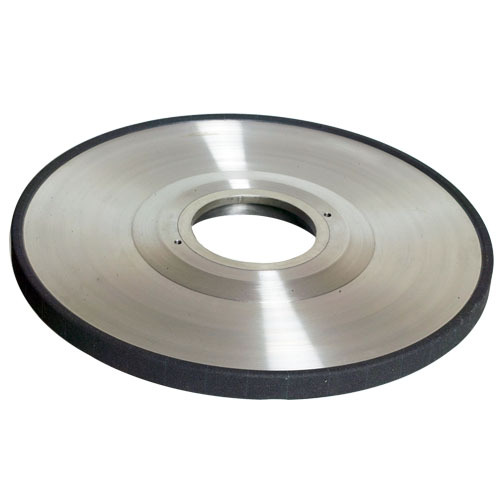

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

Cup Grinding Stone Wheel

Product Details:

- Product Type Cup Grinding Stone Wheel

- General Use Grinding, deburring, surface finishing

- Material Abrasive Stone (Aluminum Oxide)

- Type Cup Wheel

- Capacity Industrial/Professional Use

- Weight (kg) 1.2 kg

- Bond Type Vitrified

- Click to View more

X

Cup Grinding Stone Wheel Product Specifications

- 100 x 50 x 20 mm

- Smooth Surface/No Teeth

- Cup Wheel

- No Slots

- High (recommended 3600 RPM)

- Industrial/Professional Use

- Dry/Wet

- High Durability, Precision Finish

- Vitrified

- Cup Grinding Stone Wheel

- Abrasive Stone (Aluminum Oxide)

- 6 mm

- Grey

- 1.2 kg

- Grinding, deburring, surface finishing

Product Description

We have carved a niche in the industry in manufacturing and exporting wide gamut of Cup Grinding Stone Wheel. This wheel is manufactured using quality approved raw material and advanced technology by our professionals. Moreover, it goes through a series of testing procedures under the strict vigilance of our quality controllers to ensure its perfection prior to dispatch. Provided wheel is used for grinding,smoothing, shaping and polishing granite , marble, sandstone, limestone and many more. Apart from this, offered Cup Grinding Stone Wheel is available in various sizes at pocket friendly price.

Applications:

- Diamond grinding wheels are used for grinding as well as polishing stone products like stone and stock removal.

Package: Apt size of Paper case with unmatched quality carton box as per the need

Features:

- Elevated durability

- Smooth finish

- High sharpening efficiency

- Dimensional accurac

| Name | Cup Grinding Stone Wheel | HS code | 8202390000 |

| Process | Laser Welded | Material | Steel Base with Water Hole or Aluminum are available . |

| Abrasive | Diamond | Packing | Paper case |

| Size | 4",5",6",8" etc | OEM/ODM | Available |

High-Precision Industrial Grinding

Designed for professionals, this cup grinding stone wheel delivers consistent results in metalwork, masonry, and construction. The aluminum oxide composition and vitrified bond guarantee durability and optimal performance at high speeds, making complex grinding and finishing tasks efficient and precise. Its medium-fine grit ensures a balanced blend of material removal and smooth surface texture.

Versatile Compatibility and Usage

Compatible with bench grinders and rotary tools, this wheel adapts effortlessly to various industrial setups. Its robust, steel-core design supports dry or wet applications across metal, stone, and concrete, providing the flexibility needed for diverse projects. The cup shape excels in edge work and surface finishing, especially in hard-to-reach areas.

FAQs of Cup Grinding Stone Wheel:

Q: How do you install the Cup Grinding Stone Wheel correctly on a bench grinder or rotary tool?

A: To install the cup wheel, ensure your equipment is compatible and switched off. Secure the wheel using the appropriate spindle and safety flanges. Confirm the wheel is tightly fastened and spins freely before powering up, in accordance with IS 904 safety guidelines.Q: What materials can this 80 grit Cup Grinding Stone Wheel process?

A: This wheel is ideal for grinding, deburring, and surface finishing on metals, stones, and concrete. Its aluminum oxide abrasive is designed to efficiently tackle tough surfaces in both wet and dry conditions.Q: When should this cup wheel be used over a flat or segmented grinding wheel?

A: Choose the cup-shaped stone wheel for tasks that require surface finishing or edge grinding, particularly on flat or contoured workpieces. Its design provides better control and coverage in applications demanding precision.Q: Where is this grinding wheel typically employed for maximum benefit?

A: It is extensively used in industrial workshops, fabrication units, construction sites, and repair centers dealing with metal structures, stonemasonry, or concrete restoration, thanks to its high durability and ability to deliver precision finishes.Q: What is the recommended operating speed for safety and optimal performance?

A: For best results and long wheel life, operate the wheel at a recommended speed of 3600 RPM, not exceeding the maximum limit of 4300 RPM. Always adhere to IS 904 safety standards during use.Q: Why is a vitrified bond important in this grinding wheel?

A: The vitrified bond ensures the abrasive particles remain securely in place, granting high cutting speed, reliable shape retention, and resistance to heat buildupcritical for industrial, high-load grinding tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cup Grinding Wheel' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |