- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

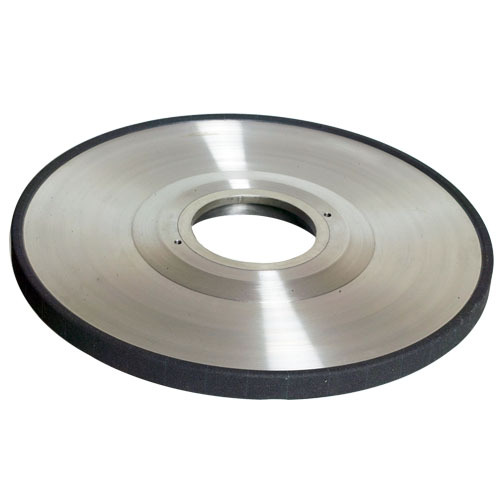

Cup Shaped Grinding Stone Wheel

Product Details:

- Product Type Cup Shaped Grinding Stone Wheel

- General Use Heavy duty grinding and shaping of hard materials such as metal, stone, and concrete

- Material Abrasive grit (Aluminum Oxide or Silicon Carbide) with vitrified or resin bond

- Type Cup Wheel

- Capacity Suitable for high load continuous grinding

- Weight (kg) Approx. 1.2 kg (varies with size)

- Bond Type Vitrified Bond

- Click to View more

X

Cup Shaped Grinding Stone Wheel Product Specifications

- High grinding efficiency, wear resistant, precise shaping

- Surface Grinding

- No slot

- Heavy duty grinding and shaping of hard materials such as metal, stone, and concrete

- Grey/Green

- 100 mm x 50 mm x 20 mm (various sizes available)

- Abrasive grit (Aluminum Oxide or Silicon Carbide) with vitrified or resin bond

- Cup Wheel

- Vitrified Bond

- 35 m/s

- Cup Shaped Grinding Stone Wheel

- Smooth edge (no teeth)

- 5 mm to 15 mm (varies with size)

- Approx. 1.2 kg (varies with size)

- Suitable for high load continuous grinding

- Solid continuous cup

Product Description

We feel glad to introduce ourselves as one of the prominent manufacturer and exporter of Cup Shaped Grinding Stone. Offered stone is used for grinding,smoothing, shaping and polishing Granite ,Marble, Sandstone, Limestone and many more. To manufacture this grinding stone our team of professionals use only quality assured raw material and latest machinery. Our offered Cup Shaped Grinding Stone is available in varied sizes as per the needs of our clients at reasonable prices.

Features:

- Application specific designs

- Light weight

- Rust proof

- Simple to fit

Applications:

- Ideal for grinding and polishing stone products like Sandstone, Granite, Marble, Limestone, etc. In addition, it is also ideal for grinding concrete, smoothing, shaping and stock removal.

Other Details:

| Name | Cup Shaped Grinding Stone | HS code | 8202390000 |

| Process | Laser Welded | Material | Steel Base with Water Hole or Aluminum are available . |

| Abrasive | Diamond | Packing | Paper case |

| Size | 4",5",6",8" etc | OEM/ODM | Available |

| Type code | Any colour and segments sizes are available for DIY design. | ||

| Usage | Mainly used for grinding and polishing stone products.such as Granite ,Marble, Sandstone, Limestone, etc.Also suitable for Grinding Concrete. Ideal for smoothing and shaping as well as stock removal. | ||

| Sample Cost | Depends on the sizes, please contact us to discuss further | ||

Precision Performance for Demanding Applications

Engineered for professional use, this cup shaped grinding wheel features a robust build and medium-to-hard hardness grade. Its high grinding efficiency and wear resistance ensure reliable results in metalworking, construction, and manufacturing environments. The wheels solid, continuous cup segment allows for precise shaping and consistent surface finishes.

Flexible Options and Customization

This grinding wheel comes in multiple grit sizes (60, 80, 100) and dimensions, catering to a wide array of user requirements. Customization options for mounting hole diameter and size guarantee compatibility with various grinding machines. OEM services are available to match specific operational needs, ensuring optimal fit and performance.

Safety and Quality Assurance

Manufactured following stringent standards, each wheel is packed in durable corrugated boxes, safeguarding them during transportation. The products heat resistance up to 250C and maximum RPM of 3600 promise safe, continuous operation under high-load conditions, instilling confidence in users regarding both safety and product longevity.

FAQs of Cup Shaped Grinding Stone Wheel:

Q: How is the cup shaped grinding stone wheel used in industrial settings?

A: This wheel is commonly mounted on bench grinders or industrial grinding machines for heavy-duty material removal, polishing, sharpening, deburring, and edge finishing on metal, stone, or concrete surfaces.Q: What materials can be processed using this grinding wheel?

A: Designed for versatility, it efficiently grinds, shapes, and polishes hard materials including metals, stone, and concrete, thanks to its abrasive grit composition and robust bonding.Q: When should I choose a medium to hard hardness grade and specific grit size?

A: Select medium to hard hardness for tough materials or heavy grinding tasks. Use coarser grits (60) for rapid material removal and finer grits (100) for smoother finishes. Custom grit options are available as per your project requirements.Q: Where can this grinding wheel be installed?

A: It is compatible with bench grinders, tool room machines, and industrial grinding equipment. Standard 31.75 mm mounting holes are provided, but custom diameters can be manufactured upon request to suit unique setups.Q: What are the benefits of choosing a vitrified bond cup wheel?

A: The vitrified bond offers superior durability, heat resistance up to 250C, and maintains structural integrity during high-load, continuous grinding operations, enhancing both longevity and precision.Q: How does this wheel ensure safe and efficient performance?

A: Manufactured for a maximum 3600 RPM and heat resistance, the wheel provides high grinding efficiency with wear resistance and precise shaping, ensuring a safe and consistent operation during heavy-duty usage.Q: Can I request OEM or custom specifications for this grinding wheel?

A: Yes, OEM and customizations are available. Options include different grit sizes, mounting hole diameters, sizes, and bond types, allowing the product to be tailored to specific application requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cup Grinding Wheel' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |