- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

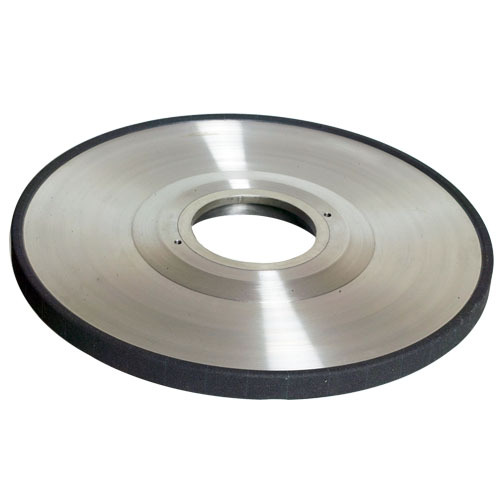

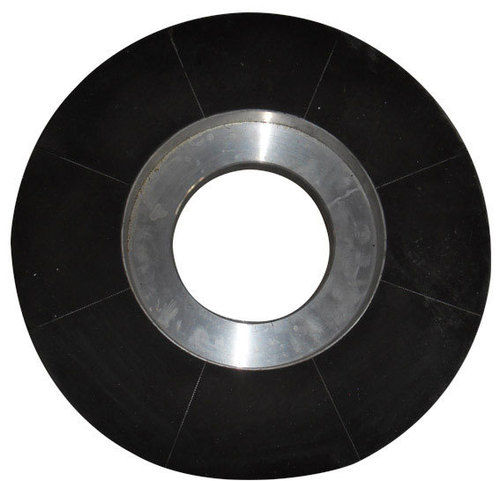

Diamond Cup Wheels

Product Details:

- Product Type Diamond Cup Wheel

- General Use Grinding and smoothing concrete, stone, masonry, and construction materials

- Material Industrial Grade Diamond, Steel Body

- Type Double Row / Turbo / Single Row (varies by model)

- Capacity High removal rate, suitable for heavy-duty applications

- Weight (kg) Approx. 0.5 - 1.3 kg

- Bond Type Metal Bond

- Click to View more

X

Diamond Cup Wheels Product Specifications

- Silver, Gold, Black (varies by model)

- Segmented / Continuous Rim / Turbo

- Up to 80 m/s

- Industrial Grade Diamond, Steel Body

- Dry/Wet Grinding

- Segmented (varies by wheel design)

- Approx. 0.5 - 1.3 kg

- 100mm / 125mm / 150mm / 180mm (customizable)

- Varies by model, typically 5-7 mm

- High removal rate, suitable for heavy-duty applications

- Diamond Cup Wheel

- Metal Bond

- Double Row / Turbo / Single Row (varies by model)

- Varies by wheel size, typically 8-24 segments

- Grinding and smoothing concrete, stone, masonry, and construction materials

- High grinding efficiency, Long service life, Low vibration

Product Description

Backed by rich industrial experience, we are able to manufacture and export our clients a broad range of Diamond Cup Wheels. The offered cup wheels are used used for polishing and grinding stone products like Granite ,Marble, Sandstone, Limestone and many more. Provided cup wheels are manufactured by our experts using excellent quality raw material and pioneering technology as per the latest industry standards with the help of latest machinery. These Diamond Cup Wheels are available in varied specifications to meet the changing needs of our clients.

Specifications:

- Technical:Laser Welded

- Grit size :30#-200# or upon customers requirements.

- Sizes:4",5",6",8" etc

- The colour and segments sizes could be made as customers requirements

Applications:

- Ideal for Grinding Concrete.

- Ideal for smoothing as well as shaping and stock removal

- Package: Right size Paper case with matchless carton box according to request

Other Details:

| Outer Diameter | Bore | Segment Dimension | Grit | Base |

| 4/100mm | M14 | 31*7*5.5 | Rough(#30) | Steel / Aluminium Base with Wafer Hole |

| 4.5/115mm | 31*7*5.5 | |||

| 5/125mm | 31*7*5.5 | |||

| 6/150mm | 31*7*5.5 | |||

| 7/180mm | 31*7*5.5 |

Customizable Grit Sizes for Precision Applications

Choose between coarse, medium, or fine grit diamond cup wheels to suit your exact application needs. Whether you require rapid material removal or a smooth, refined finish, selecting the appropriate grit size ensures optimal performance for construction, renovation, floor preparation, and surface finishing tasks.

Universal Mounting Compatibility

Our diamond cup wheels feature a standard mounting hole diameter of 22.23 mm or 20 mm, making them compatible with most angle grinders and floor grinders. This versatility allows for straightforward integration into various workflows, whether youre working on residential improvements or large-scale commercial projects.

Engineered for Heavy-Duty and Efficient Operation

With a high removal rate and robust steel body construction, these wheels are designed for demanding environments. The turbo, double row, and single row configurations (varying by model) support dry and wet grinding, achieving smooth, even finishes while maintaining low vibration and extended service life.

FAQs of Diamond Cup Wheels:

Q: How do I select the appropriate grit size for my diamond cup wheel application?

A: The choice of grit sizecoarse, medium, or finedepends on your specific project needs. Coarse grit is ideal for rapid material removal, medium for intermediate finishing, and fine for achieving a smooth, refined surface. Customization is available to match your application requirements.Q: What types of grinders are compatible with these diamond cup wheels?

A: Diamond cup wheels with 22.23 mm or 20 mm mounting holes are designed to fit most standard angle grinders and floor grinders widely used in construction and renovation projects.Q: When should I use wet grinding versus dry grinding with diamond cup wheels?

A: Wet grinding helps minimize dust and prolong wheel life, making it suitable for indoor environments and sensitive surfaces. Dry grinding is effective for quick, robust material removal, especially in outdoor or well-ventilated areas. Both options are supported, depending on your operational preference.Q: Where are diamond cup wheels typically used?

A: These wheels are suitable for both indoor and outdoor environments, optimizing grinding and smoothing operations in residential renovations, commercial constructions, and surface preparation tasks across various industry sectors.Q: What makes diamond cup wheels beneficial for construction and renovation projects?

A: Their industrial-grade diamond segments and metal bond ensure high grinding efficiency, a smooth surface finish, long service life, and low vibration. This translates to reduced labor time, consistent results, and cost-effective material removal in heavy-duty applications.Q: How does the segment design and number influence wheel performance?

A: Segment designsuch as segmented, turbo, or continuous rimand the number of segments affect grinding efficiency and finish quality. Wheels with more segments typically provide smoother surfaces and increased durability, while variations in design accommodate different removal rates and material types.Q: What is the maximum operating speed and cutting capacity for these wheels?

A: Diamond cup wheels can reach up to 12,200 RPM and deliver cutting speeds up to 80 m/s. The cutting thickness (typically 57 mm) and segment arrangement ensure high removal rates, making them ideal for heavy-duty grinding and surface finishing tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cup Grinding Wheel' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |