- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

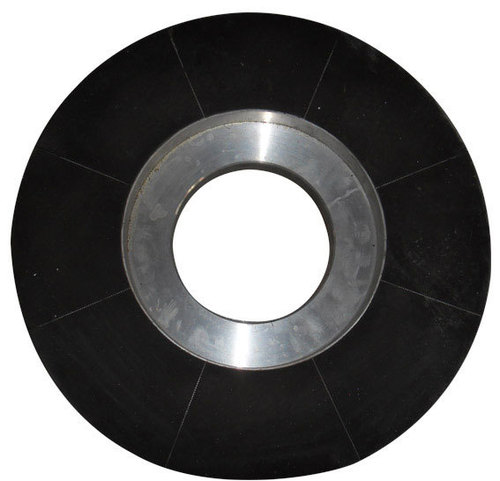

Resin Bonded Diamond Wheel

Product Details:

- Product Type Resin Bonded Diamond Wheel

- General Use Grinding and cutting hard materials such as carbide, glass, ceramics, and gemstones

- Material Diamond abrasive with resin bond

- Type Flat Wheel

- Capacity High Precision

- Weight (kg) Varies by size (typically 0.5 3 kg)

- Bond Type Resin

- Click to View more

X

Resin Bonded Diamond Wheel Product Specifications

- Continuous Rim

- Standard sizes range from 100 mm to 400 mm diameter

- up to 30 m/s

- High abrasive resistance, precision cutting, smooth finish

- No slot

- High Precision

- Resin Bonded Diamond Wheel

- Grinding and cutting hard materials such as carbide, glass, ceramics, and gemstones

- Grey

- Resin

- Varies by size (typically 0.5 3 kg)

- Continuous (no segmented) rim wheel

- Wet and Dry

- Customizable, generally 1.0 10 mm

- Flat Wheel

- Diamond abrasive with resin bond

Product Description

Owing to our adept workforce and industry experience, we are engrossed in manufacturing, exporting and supplying a broad array of Resin Bonded Diamond Wheel. Offered diamond wheel is mainly used for sharping, grinding and polishing stone, glass, ceramic, bearing, compressor, car engine processing industry, precision machining and many more. Under the guidance of adroit technical experts, provided diamond wheel is manufactured with the aid of advanced techniques by making use of finest grade aluminum. Further, this Resin Bonded Diamond Wheel can be availed from us in diverse sizes and at market leading prices.

Features:

- Sturdy built

- Perfect finish

- Anti-corrosive surface finish

- Excellent cutting speed

Other Details :

| Name | Resin Bonded Diamond Wheels | HS code | 8202390000 |

| Bond | Resin bond , Vitrified bond , Metal bond & Electroplated | Material | Aluminium & Steel |

| Abrasive | Diamond and CBN | Packing | 1pcs /box |

| Size | D:25mm-500mm T: 5mm-40mm H:10mm-127mm | OEM/ODM | Available |

| Type code | 1A1, 1V1, 1EE1, 1FF1, 3A1, 11A2, 6A9, 14A1,14A1R,11V9, 11C9, 4A2, 6A1,6A2, 12A2, 9A3, 1F1,12V2, 1L1, 14EE1, 4B1, 14E1, 4A2P, 11B2, 6A2T, 11V2, 9A1, 1A1R, 1F1, 1A8, 9A1, 9A1B,3K1, 1A1W, 4V2, 1A3, 1A2T,1A2, 12C9 14E6Q, etc. | ||

Engineered for Precision and Durability

These diamond wheels are crafted using top-grade resin bonds and high diamond concentrations, delivering outstanding abrasive resistance and consistent precision. Their compatibility with both water-based and oil-based coolants enhances versatility, while the continuous rim design ensures a smooth, chip-free finish on the hardest materials.

Versatile Application Range

Available in flat, dish, and cup profiles, these wheels are adaptable for different grinding or cutting setups. They cater to general industry demands, particularly in tool making, glass processing, and gemstone finishing, excelling in high-speed and high-precision environments.

Customizable for Your Needs

Tailored mounting holes and adjustable thicknesses ensure seamless integration with diverse machines. With standard diameters from 100 mm to 400 mm and weight variations (0.53 kg), they offer flexible solutions for manufacturers, exporters, and suppliers.

FAQs of Resin Bonded Diamond Wheel:

Q: How can I select the appropriate grit size for my application?

A: Choosing the right grit size depends on the desired surface finish and material hardness. For coarse, rapid material removal or initial shaping, choose lower grits (e.g., 80200). For fine polishing or mirror finishes, opt for higher grits (6001200).Q: What is the recommended process for using the wheel with coolants?

A: These wheels are compatible with both water-based and oil-based coolants. For wet grinding, ensure steady coolant flow to reduce heat and extend wheel life. Always follow manufacturer cooling recommendations to safeguard both workpiece and tool.Q: When should I replace the diamond wheel?

A: Replace the wheel if you observe a significant reduction in grinding efficiency, uneven wear, visible cracks, or if the maximum operating temperature or RPM is exceeded during use. Routine inspection ensures safe and effective operation.Q: Where are these diamond wheels commonly used?

A: They are widely used in industries requiring high-precision grinding or cutting, such as tool and die, ceramics manufacturing, glass processing, and gemstone finishing. Their versatility makes them ideal for manufacturers and suppliers globally.Q: What are the main benefits of using a resin bonded diamond wheel?

A: These wheels offer superior abrasive resistance, long service life, and the ability to achieve mirror-quality finishes. Their adaptability to wet and dry operations, as well as variable shapes and hardness, provides operational flexibility for different applications.Q: How do I ensure proper mounting and safety during operation?

A: Select the correct mounting hole diameter and ensure the wheel is rigidly secured before use. Operate below the 120C temperature threshold and never exceed the max RPM (3500). Adhere to standard safety guidelines and use appropriate personal protective equipment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cup Grinding Wheel' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |