- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

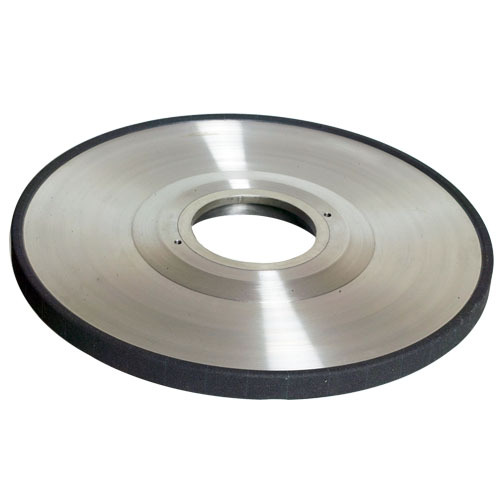

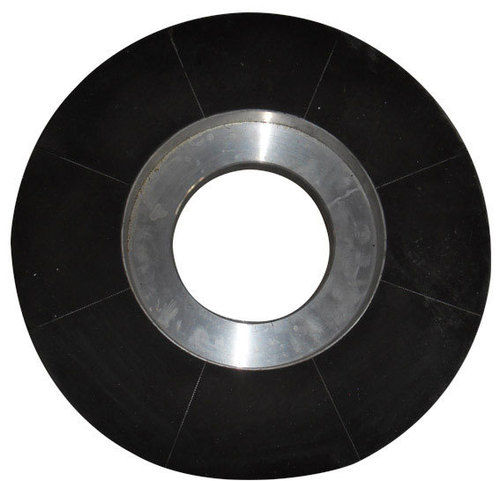

Diamond Cup Grinding Wheel

Product Details:

- Product Type Diamond Cup Grinding Wheel

- General Use Grinding and Surface Preparation

- Material Industrial Grade Diamond with Metal Bond

- Type Double Row Cup Wheel

- Capacity Designed for Heavy-Duty Applications

- Weight (kg) Approx. 0.35-0.6 kg (varies by size)

- Bond Type Metal Bonded

- Click to View more

X

Diamond Cup Grinding Wheel Product Specifications

- Double Row Cup Wheel

- 16-24 (Depending on Size)

- Approx. 0.35-0.6 kg (varies by size)

- Dry/Wet Grinding

- Turbo/Flat

- Diamond Cup Grinding Wheel

- Segmented Double Row

- 100 mm, 115 mm, 125 mm, 150 mm, 180 mm (Diameters Available)

- Metal Bonded

- 5 mm (Standard Segment Height)

- Grinding and Surface Preparation

- High Abrasive Resistance, Long Life, Efficient Material Removal

- Designed for Heavy-Duty Applications

- Industrial Grade Diamond with Metal Bond

- Silver/Gold (as per supplier batch)

- 80 m/s (Max)

Product Description

Empowered by a technologically-advanced manufacturing facility, we manufacture and export a premium quality range of Diamond Cup Grinding Wheel. This wheel is manufactured with high precision using high quality raw material with the help of contemporary machines. It is widely used for grinding all kinds of hard stone, concrete and many more and ensures fast cutting with minimal dust. Further, this Diamond Cup Grinding Wheel can be availed by our prestigious clients in varied sizes and specifications as per their application requirement.

Features:

- Dimensional accuracy

- Compact design

- High tensile strength

- Smooth surface finish

Applications:

- Diamond double row grinding cup wheel is designed for mark removal, chamfering, debarring, smoothing as well as shaping of granite, concrete, marble, porcelain tiles, natural stone, artificial stone surfaces and masonry.

- Fast cutting with negligible dust ideal for dry and wet grinding

Other Details:

| Name | Diamond Cup Wheels | HS code | 8202390000 |

| Process | Laser | Material | Diamond & Steel |

| Abrasive | Diamond | Packing | 1pcs / Blister |

| Size | 4",5",6",8" etc | OEM/ODM | Available |

Optimized for Industrial Performance

This grinding wheel excels in demanding industrial and construction environments, efficiently preparing and leveling stone and concrete surfaces. The advanced metal bonded design ensures a long tool life, even during extended grinding sessions, while maintaining a high cutting speed and superior abrasive resistance. Its heavy-duty build and enhanced corrosion resistance make it a staple tool for professionals seeking reliability and peak performance on a variety of hard materials.

Versatile Design Fits Multiple Applications

Thanks to its compatibility with both angle grinders and floor grinders, and the choice of several sizes, this diamond cup wheel adapts seamlessly to different grinding tasks. Whether prepping concrete slabs or resurfacing granite countertops, the segmented, turbo/flat tooth design ensures high material removal while minimizing heat buildup. Its robust construction supports both wet and dry grinding, offering flexibility across a range of project requirements.

FAQs of Diamond Cup Grinding Wheel:

Q: How do I properly mount the Diamond Cup Grinding Wheel on my angle grinder?

A: To install the wheel, ensure your grinder supports the standard 22.23 mm mounting bore. Securely fasten the cup wheel using the manufacturers recommended flange and tighten it in place. Always disconnect the tool from the power source before mounting.Q: What materials can this grinding wheel be used on?

A: This diamond cup grinding wheel is engineered for a range of surfaces, including concrete, granite, marble, masonry, and other tough stone materials, making it highly versatile for construction and industrial work.Q: When should I use wet grinding versus dry grinding with this cup wheel?

A: Wet grinding is preferred for reducing dust and heat generation during heavy or continuous use, while dry grinding is suitable for quick, smaller-scale tasks or when water isnt available. The wheel is designed to handle both use cases effectively.Q: Where can I use this grinding wheel is it suitable for site work?

A: The wheel is ideal for industrial and construction site environments due to its robust construction, high heat resistance, and enhanced corrosion protection. Its built for both indoor and outdoor professional tasks.Q: What is the typical lifespan of this grinding wheel?

A: Under correct conditions and proper use, the grinding wheel can last up to 5,000 square feet of material removal, though actual lifespan depends on the material, application, and grinding technique.Q: How does the wheel ensure efficient material removal and longevity?

A: Equipped with a double row, segmented design and constructed from industrial-grade diamond with a metal bond, the wheel excels in rapid, even grinding while withstanding wear and extending operational life.Q: What are the main benefits of choosing this particular diamond cup wheel?

A: Users benefit from high abrasive resistance, long working life, compatibility with multiple grinder types, efficient material removal, and the flexibility to work on various hard surfaces in both wet and dry conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cup Grinding Wheel' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |