- Home Page

- Company Profile

-

Our Products

-

Diamond Cutting Tools

-

PCD Cutting Tools

-

Core Drill Machine

-

Diamond Core Drill Bit

-

Diamond Twist Drill Bits

-

Diamond Polisher Pads

-

Electroplated Core Drill Bit

-

Diamond Wheel Dresser

-

Abrasive Sanding Belt

-

CNC Router Bit

-

Diamond Bandsaw Blade

-

Diamond File

-

PDC Cutters

-

Diamond Polishing Paste

-

Diamond Mounted Points

-

Grinding Machine

-

Diamond Saw Blades

-

Thin Circle Saw Blade

-

Carbide Rescue Blade

-

Resin Bonded Fiber Disc

-

Diamond Cup Grinding Wheel

-

Diamond Electroplate Wheel

-

Diamond Grinding Wheel

-

Diamond Cutting Tools

- Quality & Certificate

- Contact Us

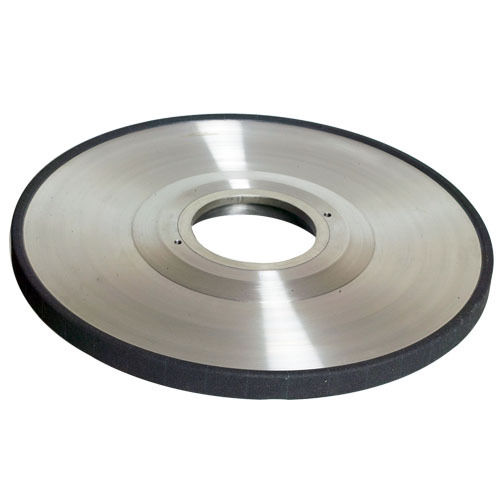

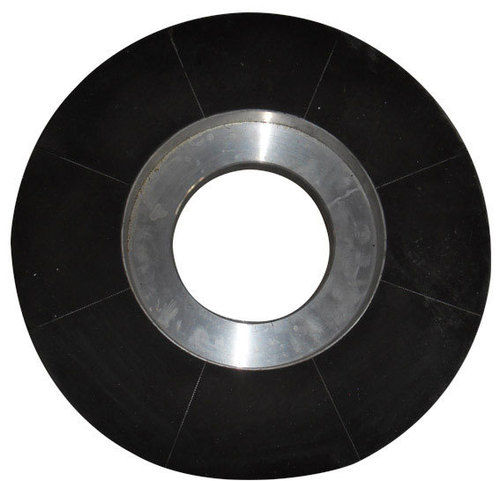

Vitrified Bond Grinding Wheel

Product Details:

- Product Type Vitrified Bond Grinding Wheel

- General Use Industrial metal and non-metal grinding, surface finishing

- Material Abrasive grain with vitrified (glass-based) bond

- Type Straight Edge Wheel

- Capacity High grinding efficiency for continuous use

- Weight (kg) Varies as per size (typically 0.5 - 5 kg)

- Bond Type Vitrified

- Click to View more

X

Vitrified Bond Grinding Wheel Product Specifications

- No slots (solid disc design)

- Standard sizes available; common: 100mm, 125mm, 150mm, 200mm, 300mm diameter

- Dry and wet grinding

- Industrial metal and non-metal grinding, surface finishing

- Customizable; usually ranges from 4 mm to 25 mm

- High durability, precise shape retention, excellent surface finish, low thermal damage

- Varies as per size (typically 0.5 - 5 kg)

- Grey

- Vitrified

- Max up to 35 m/s (subject to wheel specification)

- Vitrified Bond Grinding Wheel

- N/A (not segmented wheel)

- Abrasive grain with vitrified (glass-based) bond

- Straight Edge Wheel

- N/A (continuous abrasive surface)

- High grinding efficiency for continuous use

Product Description

Since the year of establishment, we are known as the leading manufacturer, exporter and supplying huge array of Vitrified Bond Grinding Wheel. Offered grinding wheel is efficiently manufactured by utilizing optimal quality raw material with the help of ultra-modern technique in adherence with the international industry norms. Provided grinding wheel is broadly used in the field of ceramic, diamond processing, sapphire processing for stone , glass, ceramic, bearing, compressor , car engine processing industry, precision machining, etc. Also, this Vitrified Bond Grinding Wheel can be availed from us in various sizes.

Features:

- Excellent strength

- High cutting speed

- Smooth finish

- Sharp edges

Other Details:

- 1.Diamond Concentration 75%,100%,200%,etc

- 2.MOQ: 1 Piece

- 3.OEM/ODM service

- 4.Sampling Time:7-10 days

Specification :

| Name | Grinding wheel | HS code | 8202390000 |

| Bond | Resin bond , Vitrified bond , Metal bond & Electroplated | Material | Aluminium & Steel |

| Abrasive | Diamond and CBN | Packing | purple box, 1pcs /box |

| Size | D:25mm-500mm T: 5mm-40mm H:10mm-127mm | OEM/ODM | Available |

| Type code | 1A1, 1V1, 1EE1, 1FF1, 3A1, 11A2, 6A9, 14A1,14A1R,11V9, 11C9, 4A2, 6A1,6A2, 12A2, 9A3, 1F1,12V2, 1L1, 14EE1, 4B1, 14E1, 4A2P, 11B2, 6A2T, 11V2, 9A1, 1A1R, 1F1, 1A8, 9A1, 9A1B,3K1, 1A1W, 4V2, 1A3, 1A2T,1A2, 12C9 14E6Q, etc. | ||

| Usage | Mainly used for grinding , sharping and polsihing . Widly used in the filed of PCD, CVD, PCBN ceramic, diamond processing, sapphire processing, stone , glass, ceramic, bearing, compressor , car engine processing industry, precision machining,etc | ||

| Sample Cost | Depends on the design, please contact us to discuss further | ||

Package: right size sponge in each box 1 pcs / box(purple box ) high quality carton box

Versatility of Grit and Hardness

Select from a comprehensive range of grit sizes (24 to 600 mesh) and ISO-standard hardness grades from soft to hard. This flexibility allows for tailored surface finishing, whether you require coarse material removal or fine polishing. Each wheel delivers optimal results for various grinding challenges.

Customizable Engineering for Diverse Applications

Manufactured in flat/straight, dish, and cup shapes, and compatible with standard or custom bore diameters, these grinding wheels seamlessly integrate into multiple grinding machines. Typical uses include tool room projects, surface and cylindrical grinding, as well as crankshaft and camshaft finishing tasks.

Superior Performance and Surface Quality

The vitrified bond ensures high grinding efficiency, outstanding durability, and excellent shape retention. Capable of operating up to 600C and at speeds up to 35 m/s, these wheels produce minimal thermal damage and deliver consistently high-quality results over prolonged use.

FAQs of Vitrified Bond Grinding Wheel:

Q: How do I choose the right grit size and hardness grade for my grinding project?

A: Consider the applications requirements: use coarser grit sizes (2480 mesh) for rapid material removal and finer grits (120600 mesh) for smoother surface finishes. Hardness grade selection depends on material type; softer wheels suit hard materials while harder grades work better on softer metals. All grades conform to ISO standards.Q: What is the process for mounting the vitrified bond grinding wheel on machines?

A: Verify the wheels bore diameter matches your machine; standard size is typically 31.75 mm but can be customized. Ensure the mounting surface is clean and secure the wheel with appropriate flanges. Follow manufacturer safety guidelines and confirm wheel rotation speed does not exceed 35 m/s before operation.Q: Where can these grinding wheels be used, and which shapes are available?

A: These wheels are suitable for tool room tasks, surface and cylindrical grinding, as well as crankshaft and camshaft grinding in industrial metal and non-metal applications. Available shapes include flat/straight, dish, and cup designs for various mounting and job requirements.Q: What are the key benefits of using a vitrified bond grinding wheel?

A: Benefits include high grinding efficiency, precise shape retention, long service life, and excellent surface finish quality. The vitrified bond minimizes thermal damage, allowing for continuous use even at temperatures up to 600C. They are ideal for both dry and wet grinding processes.Q: Can the wheel size, thickness, and bore be customized for special machines?

A: Yes, these wheels are available in standard diameters (100mm to 300mm), thicknesses (4 mm to 25 mm), and commonly with a 31.75 mm bore. Custom sizes and bores can be manufactured to suit specific machine models and application needs; consult your distributor, exporter, or manufacturer for details.Q: When is it recommended to use wet grinding versus dry grinding with this wheel?

A: Wet grinding is preferred when minimizing heat generation and improving surface finish are priorities, especially on sensitive materials. Dry grinding is effective for general rapid material removal. The vitrified bond supports both methods, so select based on your process goals and material characteristics.Q: What is the typical weight and capacity of these wheels?

A: Wheel weight ranges from approximately 0.5 to 5 kg, depending on size and thickness. Designed for continuous industrial use, each wheel delivers consistently high grinding efficiency and durability, making it suitable for demanding production environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Diamond Cup Grinding Wheel' category

Contact Details

Shine Peak Group (Hk) Limited

No.4028, Nanhuan Road, Binjiang District, Hangzhou - 311231, Zhejiang, China

Phone :86-571-87156536

Mr. Kelly Miao

Mobile :+8613666606123, +8613588495139

skype: jacky.huang.1981

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

Whatspp: 0086-13666606123

24 hours hotline: 0086-13666606123

Email us: hkshinepeak@aliyun.com

|

|

SHINE PEAK GROUP (HK) LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |